- 12/12/2023

- 21 Min Read

- By: Christian Schaefer

The Definitive Guide To The Porsche 996 M96 Engines

Porsche had Le Mans-sized shoes to fill with its first fully-water-cooled 911 engine. Replacing the legendary air-cooled, two-valve, single-overhead-camshaft flat-six was a water-cooled engine with double the valves and camshafts. The new engine, dubbed the M96, made more power than any air-cooled engine while significantly more fuel-efficient. Sure, it wasn’t as characterful as the air-cooled, but it did its job, helping the 996 retain its status as a benchmark sports car, albeit with some potential problems.

Several possibly catastrophic issues arose not too long into the 996’s run, giving it a reputation as a time bomb. Those problems hardly exist now, with factory and aftermarket solutions widely available and many owners performing preventative maintenance. However, it would be best to understand these engines the best you can before purchasing a used 996.

Porsche 996 Engine Guide Table of Contents |

The Non-Mezger Porsche M96

Every 996 Carrera model uses the M96, a water-cooled, naturally aspirated flat six-cylinder engine. It represented a major evolution over the outgoing 911 engine and a step into the 21st century for Porsche engineers. Between 1999 and 2001, the 3.4L engine was the only engine offered across the Carrera range. In 2002, the 996 received an update, including a larger and more powerful 3.6L engine with a revised timing chain system and a variable valve lift system.

The M96 was tasked with powering a new generation of Porsche sports cars, including the entry-level Boxster. Succeeding the last air-cooled engines was no small feat, but the M96 did so admirably, producing much more power throughout the rev range while being cheaper to make, easier to maintain, and more fuel efficient. Although it angered Porsche purists, the switch to water-cooling was necessary for the 911 to make it into the modern era after clinging to its ‘60s-based roots for 30 years. It provided the cooling capacity needed for the dual overhead camshafts and four valves per cylinder needed to keep the 911 competitive.

However, it wasn’t all good, as the M96 developed early teething issues. Its faults were enough to scare away potential second-hand buyers and have defined the chassis forever, but now present much less of an issue thanks to the aftermarket. Power-adding modifications are available for the M96 from a wide range of tuners and shops for those looking for more. Standard bolt-ons like freer-flowing intakes and exhaust work well with a remapped ECU and can provide a noticeable bump in performance. Companies like Flat 6 Innovations can turn the Carrera’s M96 into a bigger and stronger beast, providing custom camshafts and pistons, better-flowing cylinder heads, and increased displacement. However, that work will cost nearly as much as a good 996.

There was, however, a hot-rodded Carrera engine offered directly from the factory. By buying a 2004 Carrera 40th Anniversary or ticking the X51 option box on the build sheet, the M96 engine made 25hp more than all other Carreras. It was a thorough makeover for the M96, receiving this comprehensive list of improvements:

- Ported intake manifold runners and cross-piece

- Larger, reshaped exhaust manifolds

- Ported cylinder heads

- Intake camshafts with more duration and modified intake/exhaust valve timing

- Reprofiled intake valve springs

- Modified oil baffle and sump

- Remapped DME control unit

Porsche Carrera M96 Common Problems

Although the M96 engine can be a great performer capable of many miles, it wasn’t Porsche’s best out of the box. Some of its shortcomings are severe enough to put people off of ownership; others are issues common to any water-cooled engine. Watch for any of the problems below as you shop for an M96-powered Porsche, but don’t let them scare you away. There’s a fix for every potential issue; you can find them just a bit farther down in this guide.

Intermediate Shaft (IMS) Bearing

The crankshaft indirectly drives the camshafts in the M96 through the intermediate shaft. There are two sprockets on the shaft, one on either end, and they use chains to connect to and drive the camshafts. The plain bearing Porsche fitted to the clutch side of the shaft failed relatively quickly in most engines, leading to engine damage. When that occurs, the oil begins to wear out the bearing prematurely, and metallic bits get sent through the engine at best. In a worst-case scenario, the bearing seizes and throws half the engine out of time, causing catastrophic damage. We offer two solutions to this problem below in the maintenance and upgrades section.

Cylinder Liner Cracking/D-Chunk

Cylinder liner cracks may result from the engine’s natural vibration and twisting under normal operating conditions. In rarer cases, the cracks may result from broken water pump impeller bits in the cooling passages. When that happens, the blockages cause localized hot spots that can cause cracking. When they crack, the top of the cylinder breaks outward into the water passage, ruining the cylinder. This problem often occurs in gently driven 911’s and is most common on the 3.4L engines.

Cylinder Bore Scoring

Although the IMS bearing is the flashy failure that the internet has morphed out of proportion, this is what they ought to be worried about. Cylinder bore scoring is a death knell for the engine or your wallet as it requires major repair, if not complete replacement. With that said, repair is actually the preferred method because replacing the engine with another one, rebuilt as stock or not, doesn’t solve the issue.

Bore scoring is caused when the piston skirt’s iron coating flakes off at the bottom of the piston stroke as the skirt peaks out of the bottom of the bores. Uncoated piston skirts then contact the cylinder walls and gouge them, letting oil by, ruining the piston-to-wall clearance, and destroying the cylinder. It’s a significant issue, and it’ll make itself apparent through one or more of these symptoms:

- Loud tick/knock from the affected cylinder

- Increase in oil consumption

- Sooty tailpipes

- Soot in the engine oil

- Oily/sooty bumper cover

- Cylinder misfires

Due to the different expansion rates provided by the cylinder walls and the forged pistons, and a less-than-perfect rod/stroke ratio, all 3.4 and 3.6 non-Mezger engines can and will likely develop this issue. The only guaranteed fix is to send the engine case off to have the original cylinders removed and replaced by a more traditional cylinder liner and piston. It’s a significantly costly endeavor—if done correctly, it’ll likely be more than what most used 996s are worth—but the results are a bulletproofed engine proven free of any future issues.

Oil Leaks

If severe enough, the early 996s had leaky rear main seals that would affect clutch operation. Porsche quickly remedied the issue, producing an updated seal. Install a new rear main seal for extra peace of mind whenever you service the IMS bearing or clutch. The IMS cover seal also had leak issues, though this has been updated. Immediately inspect the intermediate shaft and bearing if any leaks are in this area, as they can be a sign of a more significant problem.

You can also find oil weeping from your oil cooler. Porsche uses an oil-to-water cooler, and its o-rings get brittle and leak over time. Because it's a water-to-oil cooler, the leaking oil can contaminate the coolant, creating a milkshake-like sludge. If you notice a leak here, fix it sooner rather than later.

Crankshaft to Intermediate Shaft Timing Chain Tensioner Guide

The factory timing chain guide is plastic—great for easy production and weight—but it's not without its faults. The guide’s center point and the pivot pin are weak areas where failure occurs as repeated exposure to heat weakens the plastic. Porsche and aftermarket companies offer replacement guides, but the aftermarket is aluminum, and the Porsche piece is still plastic.

Air Oil Separator

The air/oil separator (AOS) pulls oil vapors and pressure from the crankcase and sends them through the intake manifold. The vacuum supplied by the AOS also helps to seal the low-tension piston rings. Failure of this part allows excess oil to be directed through the intake and burned, leading to oil consumption misfires from fouled spark plugs. The entire air/oil separator system should be considered a maintenance item and periodically replaced.

Water Pump

The water pump is another maintenance item you cannot overlook just because it operates well on the day. The water pump installed at the factory uses a plastic impeller to drive the coolant through the engine. Owners have seen those impellers break apart and get sent through the engine, clogging coolant passages and the thermostat. If not replaced on schedule, the pump will fail, allowing the impeller to contact the engine block, damaging it, and sending impeller bits through the engine again.

Upgrading to a water pump with a metal impeller is the best way to prevent plastic from being sent through the engine. However, replacing the water pump at the recommended interval is the only way to avoid extra damage. Regardless of which type of water pump you choose, replace it every 3-4 years as preventative maintenance.

Variocam Solenoid

Porsche introduced their “VarioCam” on the M96. Their variable valve timing system gave the 996 engine a better torque curve and economy across the entire rev range. Failure of the VarioCam solenoid will cause a rough or inconsistent idle and a few trouble codes. A brittle or worn seal will allow contaminated oil to enter the solenoid, though general age can also cause failure.

Cracked Ignition Coils

The ignition coils sit close to the exhaust, and even though there’s a heat shield to help protect them, they still experience constant heat cycling. The heat cycling creates cracks in the tops of the ignition coil, debilitating its effectiveness. A bad ignition coil will cause a misfire and check engine light. Inspect the ignition coils each time you replace the spark plugs. Even if they look ok, we recommend replacing them with preventive maintenance.

Connecting Rod Bolt Failure

If you ever experience this, consider yourself the unluckiest of the unlucky. The connecting rod bolts are torque-to-yield bolts stretched at their final torque setting to provide the required clamping load on the rod bearing cap. The added stress and loading of the engine at high RPMs further stretch the rod bolts to the point where they can become loose or break completely. This issue rarely occurs and is seen only in an engine abused high in the rev range. A rod bolt failure will lead to significant engine damage. Upgrade your connecting rods and bolts if your engine regularly goes to the track.

Porsche Carrera M96 Maintenance Recommendations

The following service schedule is per Porsche, although we may recommend more frequent service as preventative maintenance and extra peace of mind for some items.

Annual Maintenance for vehicles driven less than 9,000 miles

- Engine oil and filter changes are required at least every two years for vehicles not meeting the scheduled major service intervals. 996 Engine Oil Change Kits

- Inspect and remove external debris from radiators and air inlets.

- Check engine oil level.

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

Minor Maintenance at 15,000, 45,000, 75,000, and 105,000 miles, etc.

- Change the engine oil and filter.

- Check the air filter condition and replace, if necessary. 996 Air Filters

- Replace the cabin filter. 996 Cabin Air Filters

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

- Check the condition of coolant hoses.

- Inspect and remove external debris from radiators and air inlets

- Check coolant level and antifreeze protection. Antifreeze Tester

Major Maintenance at 30,000, 60,000, 90,000, and 120,000 miles, etc.

- Change engine oil and filter.

- Replace spark plugs. 996 Ignition Coil Kits

- We also recommend replacing the ignition coils at this time since they are prone to cracking through the thousands of heat cycles they experience, and it’s the same amount of labor and work to change them while servicing the spark plugs.

- Replace the air filter.

- Replace the cabin filter.

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

- Check the condition of coolant hoses

- Inspect and remove external debris from radiators and air inlets.

- Check coolant level and antifreeze protection.

- Inspect the exhaust system for leaks and damage, and check exhaust mounts.

- Check throttle actuation.

- Inspect the fuel system for damage and correct seating of line connections.

- Check serpentine belt condition.

Additional Maintenance at 60,000 miles

- Replace the serpentine belt. 996 Serpentine Belts

- Replace the fuel filter. 996 Carrera Fuel Filter, 996 Carrera 4 Fuel Filter

Porsche Carrera M96 Maintenance & Upgrades for the Street

The M96 engine is very reliable on the street, with routine maintenance and a few upgrades. Whether you just picked up a new-to-you 996 or have owned one for years and want to improve on it, here’s what you will need.

Air/Oil Separator with Hoses

The air/oil separator is like a PCV valve, designed to relieve crankcase pressure by drawing the oil vapors into the intake stream to be burned during combustion. The separator and hoses are made of plastic, and like any other plastic component found near heat, it is prone to degradation and cracking. You’ll have a vacuum leak and a misfire code when that happens. The air/or separator diaphragm can also fail, sucking oil into the intake. Oil consumption, rough idle, and blue exhaust smoke are all indicative of a failing AOS.

Spark Plugs and Ignition Coils

Spark plugs need to be replaced every 30,000 miles. While they can sometimes last longer, the ignition coils are prone to cracking due to their position in the engine bay and proximity to the exhaust. That cracking will lead to misfires and driveability issues. It’s best to replace both the spark plugs and ignition coils together.

Water Pump with Metal Impeller

A water pump is a maintenance item, and we recommend replacement every 3-4 years, regardless of the kind of pump. The factory water pump had a composite impeller that cracked and broke with age. A water pump failure will prevent coolant from circulating throughout the engine, causing it to overheat. It can also spread the broken impeller bits throughout the engine and clog the coolant passages. A metal impeller water pump can prevent these failures, add reliability to your cooling system, and save your engine from significant damage.

CSF Radiators

The end caps on the factory radiators are plastic and crimped onto the aluminum core. They’re another area where the plastic will weaken with age and crack, leaking coolant. CSF radiators are a complete aluminum construction with aluminum end tanks. They also have a larger double-row core, which helps increase both cooling capacity and efficiency, a must-have upgrade for any 911 seeing aggressive street use.

LN Engineering Magnetic Drain Plug (106-07)

A magnetic drain plug will keep metal debris and shavings from circulating throughout the engine, accelerating wear on critical components. The plug can also help detect significant engine wear or problems; if you notice a lot of metal collecting on the magnet when you remove it for oil changes, there is probably an issue. An oil analysis in conjunction with a magnetic drain plug will help notify you of any possible problems related to the health of your engine.

LN Engineering IMS Bearing Retrofit Kit

The IMS Bearing Retrofit Kit replaces the factory IMS steel ball bearing with a ceramic hybrid ball bearing. The improved bearing and other components in the kit add strength and reliability to this sensitive engine area. Service requirements for the IMS Retrofit kit are every six years or 75,000 miles. If no documentation proves this bearing has been upgraded, it should be the first upgrade performed.

- Single Row (2000-2005 Carrera & Boxster)

- Dual Row (1997-2001 Carrera & Boxster)

LN Engineering Chromoly Engine Oil Pump Hex Drive

The factory oil pump drive is a mild-steel, non-heat treated drive that can easily break apart and fail on any engine driven hard. Upgrading the oil pump drive with a Chromoly heat-treated version from LN Engineering is a low-cost upgrade for both street and track cars.

LN Engineering Oil Sump Kit

The M96 engine uses an integrated dry-sump system. Unlike the air-cooled engine with a separate oil tank, Porsche cast the oil tank directly into the bottom of the M96 engine case. It was great for packaging but led to oil starvation issues when pushed hard. Any 996 seeing track time should utilize the oil sump and pump upgrades. Ensure your oil level is always at the high mark if you’re using the factory sump plate to help prevent oil starvation.

The LN Engineering oil sump kit provides an additional half a quart of oil to the crankcase while lowering the oil pan by a quarter of an inch. That reduces crankcase windage oil consumption and reduces the load on the air/oil separator. This is an often-overlooked upgrade for owners who drive their 911 and like to take their car to the track occasionally.

Porsche Carrera M96 Maintenance and Upgrades for the Track

The same parts used to sure-up a street-driven engine don’t include those needed to go racing. Constant high-RPM usage puts a different strain on the engine than normal driving, something the M96 wasn’t necessarily built for. However, with these upgrades, you shouldn’t have to worry about something failing because of a lack of durability.

CP Carrillo Connecting Rods

If you are rebuilding your M96 engine for the track, one area to pay close attention to is the connecting rods. The issue is that the factory connecting rod bolts cannot withstand the engine load placed on them at the high end of the RPM range. That usage causes the rod bolts to stretch beyond their capacity, and eventually, they will become loose or break, leading to engine damage or complete failure. The CP Carrillo connecting rods offer stronger and lighter rods and stronger bolts that will add reliability and strength to your engine.

Motorsport Air/Oil Separator

The motorsport air/oil separator upgrades the factory unit to one better suited to the stresses of a race track environment. It is physically larger than the OE piece and contains more chambers to better keep oil out of the intake tract. This part requires modifications for installation.

LN Engineering Deep Sump Oil Pan Kit

The deep-sump oil-pan upgrade kit adds 2.0 quarts of additional oil capacity to your engine. This does two things; first, it lowers the oil level in the crankcase so it doesn’t get aerated. Second, the included windage tray prevents oil from sloshing around during corning. The X51-style baffle in the kit keeps the oil from moving away from the oil pickup tube, preventing oil starvation. Upgrading the pan and baffling is the easiest way to ensure a constant healthy oil pressure on the race track.

LN Engineering Aluminum Timing Chain Tensioner Guide

As you may have noticed by now, there is a theme with all of the failure-prone plastic engine components used in the M96 engine, and the timing chain tensioner guide is no different. The LN Engineering timing chain tensioner guide replaces the factory plastic guide and pressure pin with a billet aluminum guide and steel pressure pin. It also comes with a new guide pad, though that is replaceable separately.

LN Engineering IMS Solution Kit

The IMS Solution Kit by LN Engineering is the ultimate solution to IMS problems and maintenance. This kit replaces the factory IMS ball bearing with an oil-pressure-fed plain bearing that requires no future servicing or replacement. The new bearing is designed to last for life and is a must-have for track cars and streetcars. By resolving the weakest point in the engine, you can focus your time and effort on driving, knowing you have the most durable and reliable IMS replacement on the market.

However, there is a slight catch. Porsche picked up on the problem early on and began switching bearings during the 2000 model year. The changeover wasn’t completed until 2001, so 2000 and 2001 model Carrera and Boxsters can have either of them.

- Single Row Kit (2000-2005 Carrera & Boxster)

- Dual Row Kit (1997-2001 Carrera & Boxster)

The Mezger-Based Porsche M96

I wouldn't blame you if you didn't know who Hans Mezger was, but I'm certain familiar you're with his work. In the early sixties, he led the development of the 911's air-cooled flat-six before moving to the motorsport side of the engineering department. There he helped create some of the most famous Porsche prototypes and was instrumental in turbocharging the 917's that would later lend its knowledge and experience to the 930. After that, it was mostly small stuff, like developing the TAG 1.5L V6 that powered McLaren to multiple F1 championships and modifying his air-cooled flat-six with water-cooled, four-valve cylinder heads for the 936, 956, 959, 962, and 911 GT1. It's the latter engine that Porsche chose to modify and feature in their 996 Turbo, GT2, and GT3 street cars beginning in 1998.

Along with the bottom end from the Mezger-designed air-cooled models with water-cooled cylinders and heads, these engines received a proper dry-sump oiling system with a separate oil tank. Porsche knew the engine from their three decades of success at Le Mans, having pushed them to around 800 hp by the early nineties. All of the racing development helped make the Mezger-based engine incredibly reliable on the street and track, no matter which model it was equipped in. However, because of that, these "Mezger" engines have no relation to the standard M96 in the Carreras as they're fundamentally different engines. Available in normally aspirated and turbocharged variants, the Mezger-based M96 is the one to use for significant and reliable power.

Mezger-Based Porsche M96 Common Problems

The Mezger-based M96 engine is one of the best Porsche has ever produced and is nearly bulletproof from the factory. Its design was a pure racing engine derived from the Porsche 911 GT1-98 that won Le Mans and, therefore, didn’t suffer from the same issues found in the M96 Carrera engines. As such, each variant needs very little preparation for aggressive track duty. Here are a few upgrades that can be utilized on the high end of the 996 model range.

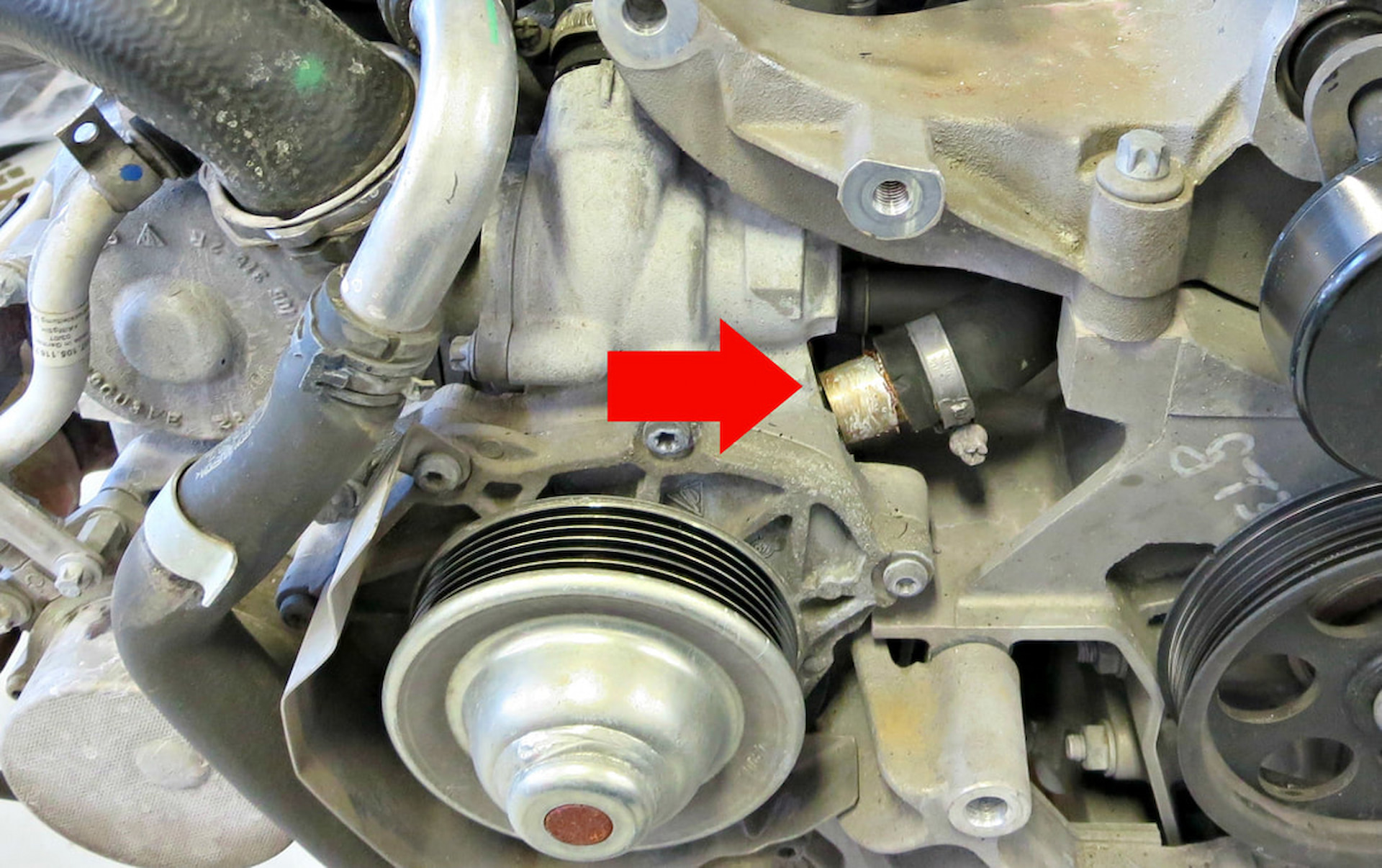

Coolant Pipe Failure

The factory aluminum coolant pipes used in a few places throughout the engine are secured into their housings with an adhesive. Over time and through thousands of heat cycles, the glue breaks down, leading to the coolant pipes loosening and coolant leaks. If not addressed preemptively, this can leave you stranded and with significant engine damage due to cooling loss. The best solution is to have a Porsche specialist repair facility “pin” the coolant pipes and reseal them. It’s a permanent fix that should last the life of the vehicle. Image courtesy of Joe Leggs.

Cooling System Leaks

More plastic is in the cooling system on the factory radiators. The end caps on the factory radiators are plastic and crimped onto the aluminum core. They are another area where the plastic will weaken over time through thousands of heat cycles and eventually crack and leak coolant. Replacing them with all aluminum CSF radiators will rid them of plastic-related cracks and leaks. They also have a larger double-row core, which helps increase both cooling capacity and cooling efficiency, a must-have upgrade for any 911 seeing aggressive street use.

Mezger-Based Porsche M96 Maintenance Recommendations

The following service schedule is per Porsche, although we may recommend more frequent service as preventative maintenance and extra peace of mind for some items.

Annual Maintenance for Vehicles Driven Less Than 9,000 Miles

- Engine oil and filter changes are required at least every two years for cars not meeting the scheduled major service intervals. 996 Engine Oil Change Kit Turbo/GT2, GT3

- Inspect and remove external debris from radiators and air inlets

- Check engine oil level

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

Minor Maintenance at 15,000, 45,000, 75,000, and 105,000 Miles, etc.

- Change engine oil and filter

- Check the air filter condition and replace it if necessary. 996 Air Filter

- Replace cabin filter. 996 Cabin Air Filters

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

- Check the condition of coolant hoses

- Inspect and remove external debris from radiators and air inlets

- Check coolant level and antifreeze protection. Antifreeze Tester

Major Maintenance at 30,000, 60,000, 90,000, and 120,000 Miles, etc.

- Change engine oil and filter

- Replace spark plugs

- We also recommend replacing the ignition coils at this time since they are prone to cracking through the thousands of heat cycles they experience, and it’s the same amount of labor and work to change them while servicing the spark plugs.

- Replace air filter

- Replace cabin filter

- Inspect for oil leaks and ensure that underbody splash shields and coverings are securely attached.

- Check the condition of coolant hoses

- Inspect and remove external debris from radiators and air inlets

- Check coolant level and antifreeze protection.

- Inspect exhaust system for leaks and damage, check exhaust mounts

- Check throttle actuation

- Inspect the fuel system for damage and correct seating of line connections

- Check the serpentine belt condition

Additional Maintenance at 60,000 Miles

- Replace the serpentine belt. 996 Turbo/GT2, GT3

- Replace the fuel filter. 996 Fuel Filter

We know this looks like a lot, and it is, but everything here is what makes the M96 variants what they are. It’s not a perfect engine, but with some elbow grease and proper maintenance, it’ll contend with the best of ‘em. As always, if you like our content and want to watch and read more, follow our DIY blog and subscribe to our YouTube channel.