- 01/16/2024

- 26 Min Read

- By: Christian Schaefer

The Definitive Guide To Porsche 997 Engines (M96.05, M97, MA1)

The Porsche 997 will forever be a bright spot in the 911 lineage. It brought back the 911’s classic lines and provided an endlessly usable base for a sports car. Nowadays, they’re the last bastion for mechanical simplicity in a 911, making them a target for many potential buyers. However, they can be risky as they have more than a few troubles with some of their engines. Before diving in wallet-first, do some reading to prepare yourself for potential ownership.

Porsche 997.1 Engines

It didn’t matter that Porsche knew their 996 Carrera engines had several catastrophic flaws; they had no choice but to band-aid them and send ‘em out in the 997. For all intents and purposes, the updated M96 and “new” M97 engines were better and less prone to failure, but they were far from perfect. Almost two decades on from the 997’s introduction, the outlook for these flawed but iconic engines looks better than ever as the aftermarket did what Porsche engineers couldn’t or wouldn’t, and solved all of the issues.

Then there are the Turbo and GT cars. Built with significantly more performance in mind, their engine share only a basic designation with those of the Carreras. Developed from decades of success at Le Mans, they represent the peak of Porsche engineering from the early days. In the 997, they’re as robust and powerful as ever and feature several evolutions in a short time. The cars they come in can be had at a relative bargain, but most have ascended into the stratosphere, so consider yourself lucky to have one on your horizon.

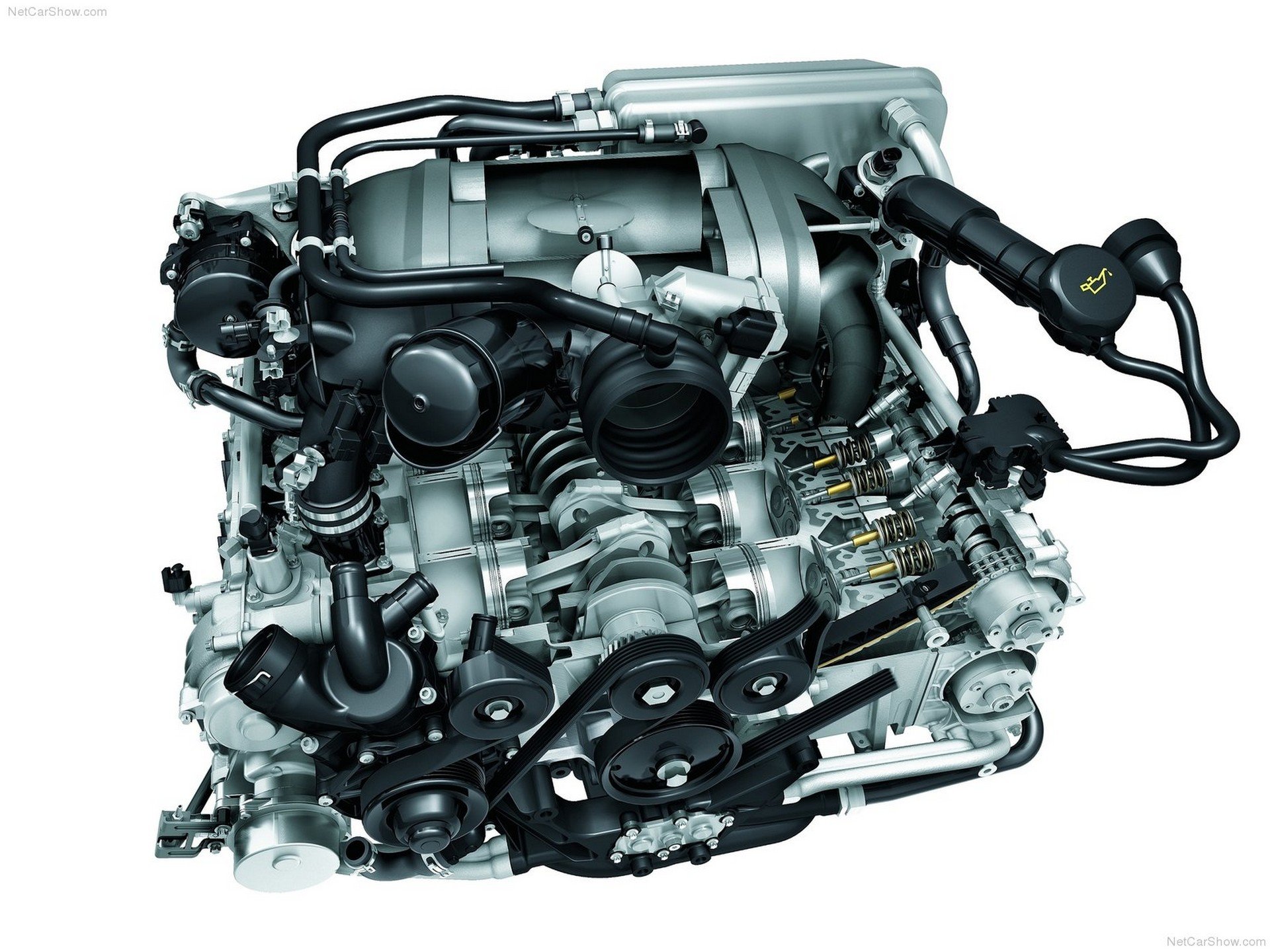

M96.05 - 2005-2008 Carrera, Carrera 4, Targa 4

The engine fitted to the base Carreras is the final revision of the 996’s power plant. Barring small changes with coolant ports and SAI pump mounting, the M96.05 is very much the same 3.6L engine as found in the 996.2. Porsche began addressing the IMS bearing failures just after 997 production began, so the .05 engines can have the serviceable 996 bearing or the larger, non-serviceable 997 unit. While the revision wasn't perfect, 997 bearing failure is far rarer. Factory peak power outputs remained equal to the 996.

M97.01 - 2005-2008 Carrera S, Carrera 4S, Targa 4S

The M97.01 featured in all S variants is the largest engine ever fitted to a Carrera at 3.8L thanks to a 3mm larger bore over the 3.6L. Larger cylinder head ports and camshafts, bespoke intake and exhaust manifolds, and a different DME made the most of the displacement, bumping power by about 30 hp. This engine also uses a mechanical vacuum pump driven off of a camshaft for a more consistent brake vacuum.

M97.01S - 2006-2008 X51 Powerkit

In 2006, Porsche began offering the X51 Powerkit on all Carrera S models as a standalone, $10,000 option. The engine kept its displacement but received various improvements to pump up power. The most extensive came from modified cylinder heads with enlarged camshafts. Supporting those were a GT3-style intake manifold, larger exhaust headers, and revised engine mapping. Corresponding reliability improvements included a third radiator and a deeper oil pan with baffling.

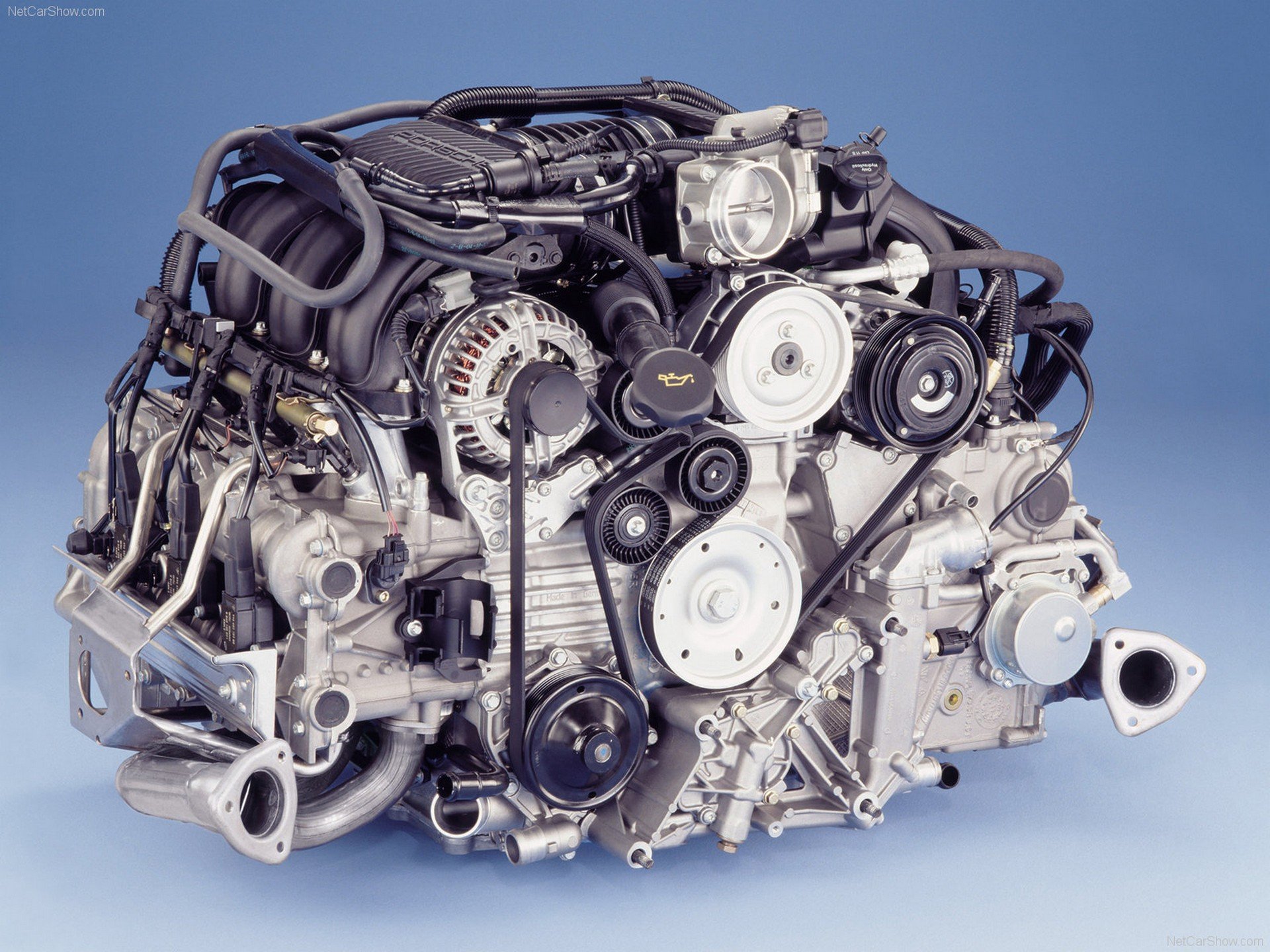

M97.70 - 2007-2008 Turbo

The M97.70 is the M96.70 with only a few revisions. The largest change came from Variable Turbine Geometry turbochargers or VTGs. These turbochargers have adjustable blades on their turbines, allowing them to sit at optimal efficiency levels throughout the rev range. In other words, the Turbo has a flat torque curve right through the middle 40% of its rev range. Coolant pipe failures did affect the 997 Turbo, same as the 996, though fixes are well documented.

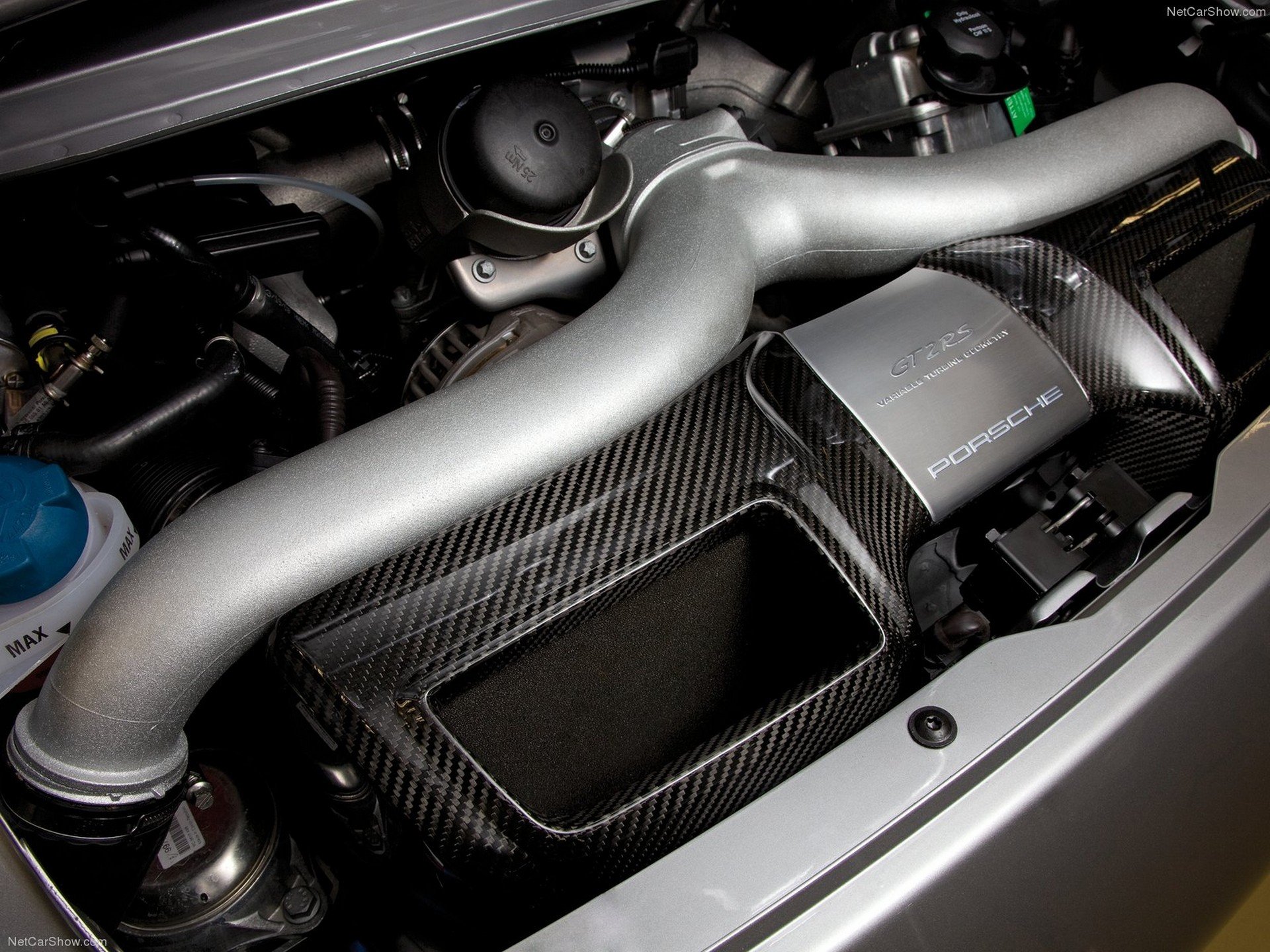

M97.70S - 2008 GT2

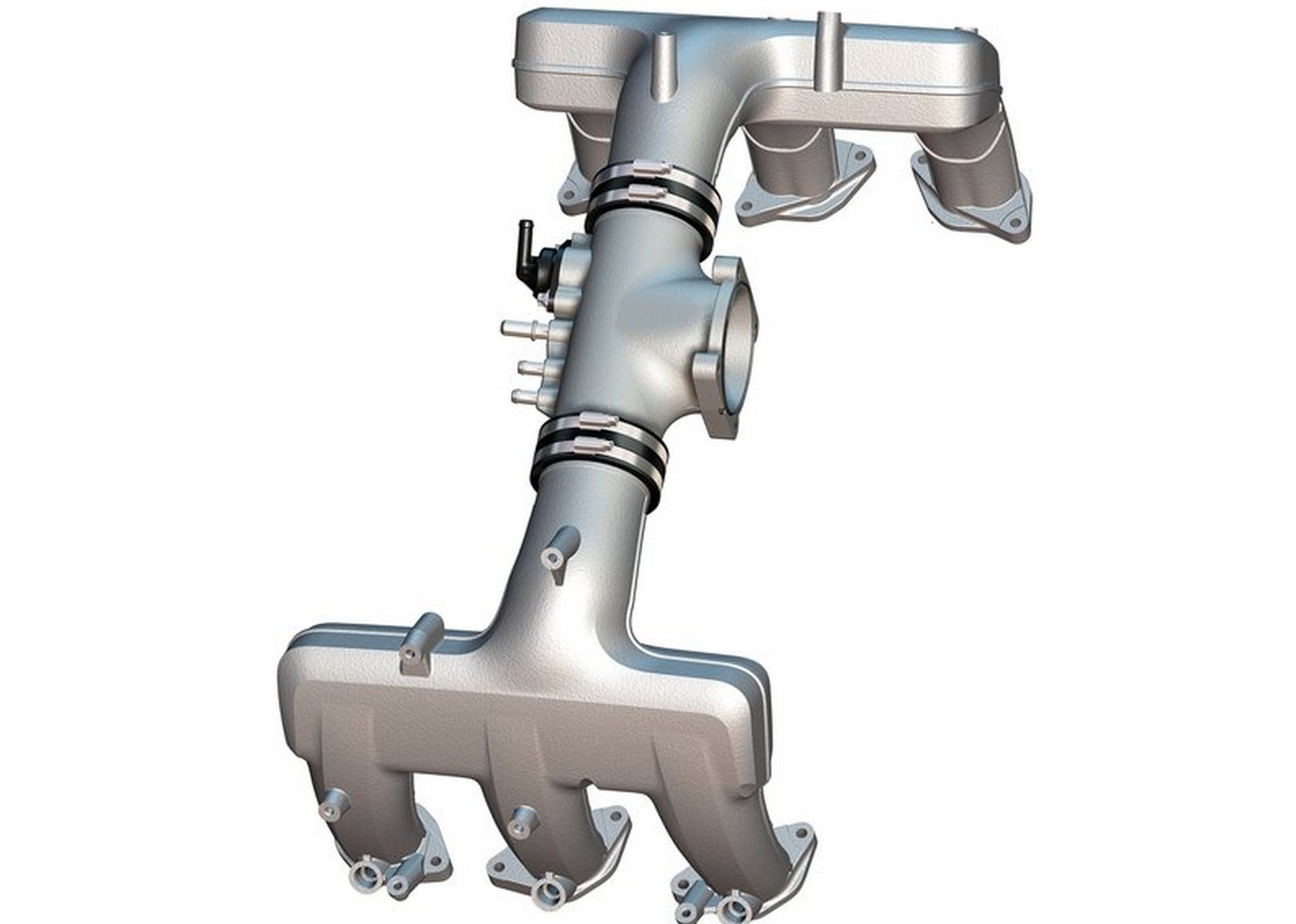

The GT2 was the only 997.1 offered with turbocharging and rear-wheel drive. Porsche developed the engine from the Turbo’s unit and pulled significantly more power from the same displacement. Larger turbochargers with variable turbine geometry provided more airflow and higher boost pressure, forcing higher power figures. Additionally, the intake manifold was a new design, dubbed the “expansion” manifold (shown above); it employed a larger center runner with shorter and narrower individual cylinder runners to allow for greater expansion in the combustion chamber. In short, it improved combustion efficiency, allowing for more power with less heat.

M97.76 - 2007-2008 GT3 & GT3RS

The M97.76 is the 997.1 GT3 and GT3RS engine. It’s an evolution of the unit found in the 996.2 GT3, carrying the same Mezger design. As the basis for the Carrera-based race cars, the engine is designed for high-rpm naturally-aspirated power, so it utilizes the highest redline and compression ratio of all early engines. Modified cylinder heads, an improved intake manifold, larger camshafts, and various other small changes make up the revisions for the 997. Displacement stayed the same at 3.6L, but horsepower jumped up by around 35, and the torque was raised by 15 lb-ft. This engine is the only one of those in the 997 not to use variable valve lift. The Variocam Plus tappets were very heavy, so they were ditched for solid, lightweight units.

Learn More About The Porsche 997 911 In Our Buyer's Guide

Porsche 997.2 Engines

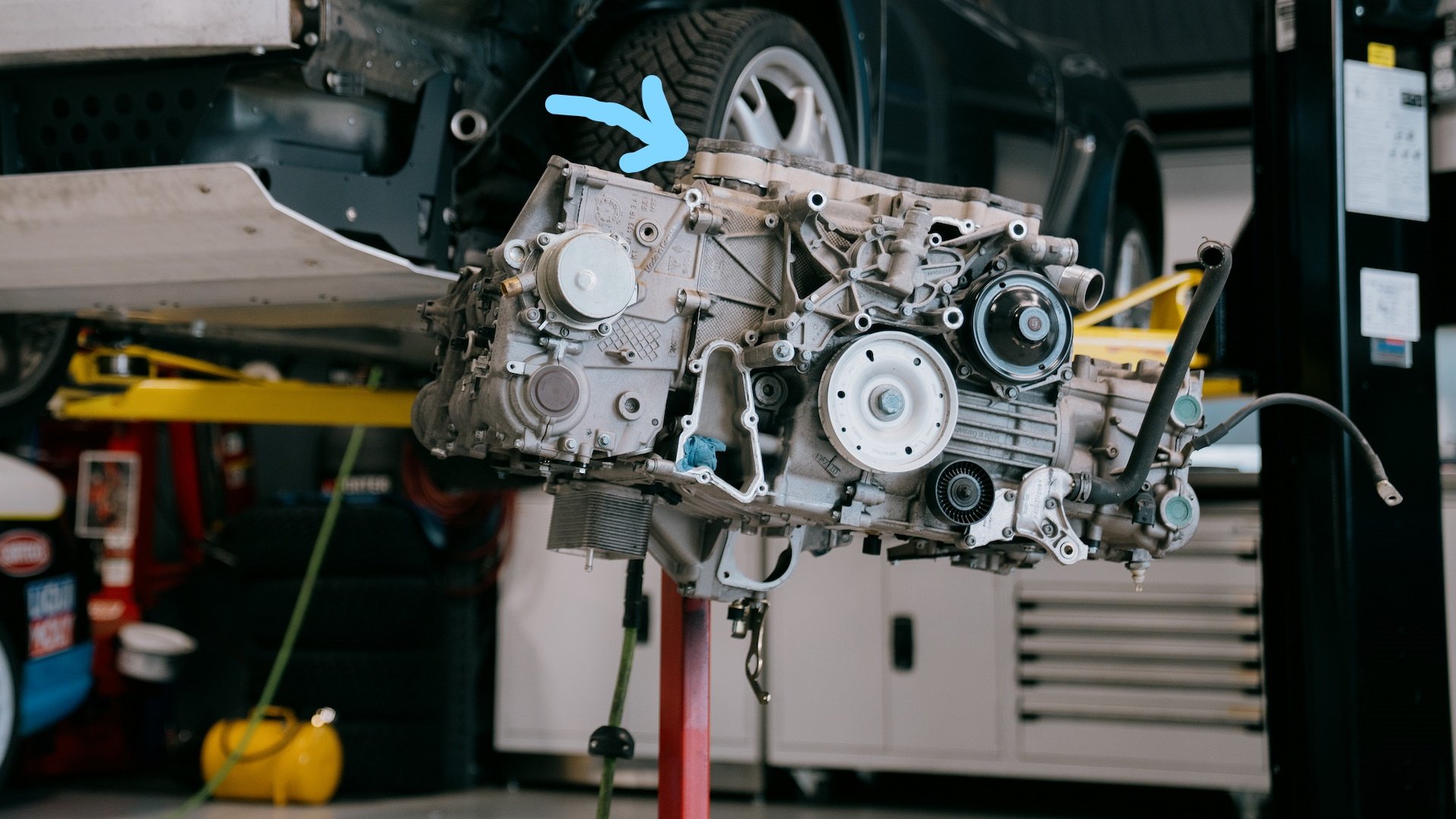

The second half of 997 production introduced an entirely new line of engines for the 911. The M96/M97 lasted around fifteen years and powered some of the best-water-cooled non-Turbo or GT models out of Stuttgart. However, rapidly changing emissions standards, unreliability by Porsche’s standards, increasing pressure from competitors, and a looming model change led Porsche to develop a replacement.

The new engines received a similar naming structure to their predecessors, going by the 9A1 or MA1 name. Both names are acceptable; however, Porsche refers to them as the MA1 in factory technical documents. Carrera and Carrera S variants are MA1.02 and MA1.01, respectively, while the Turbo retained its .70 designation. The GT models kept their Mezger-based M97 engines until the end of the 997.

The new engine was built around a closed-deck engine case made from AluSil. The increase in cylinder wall strength and use of AluSil gave the cylinders far better protection from the cylinder bore scoring and D-chunks that affected the Lokasil M96/M97 cylinders. The only downside to that design is the limited cooling offered by the reduction in coolant passageways. An open deck allows the coolant to nearly fully encompass the cylinder, while a closed deck has only a few coolant passages running through the case material. Overheating is not a common issue, though keep a close eye on the coolant temps at any track event.

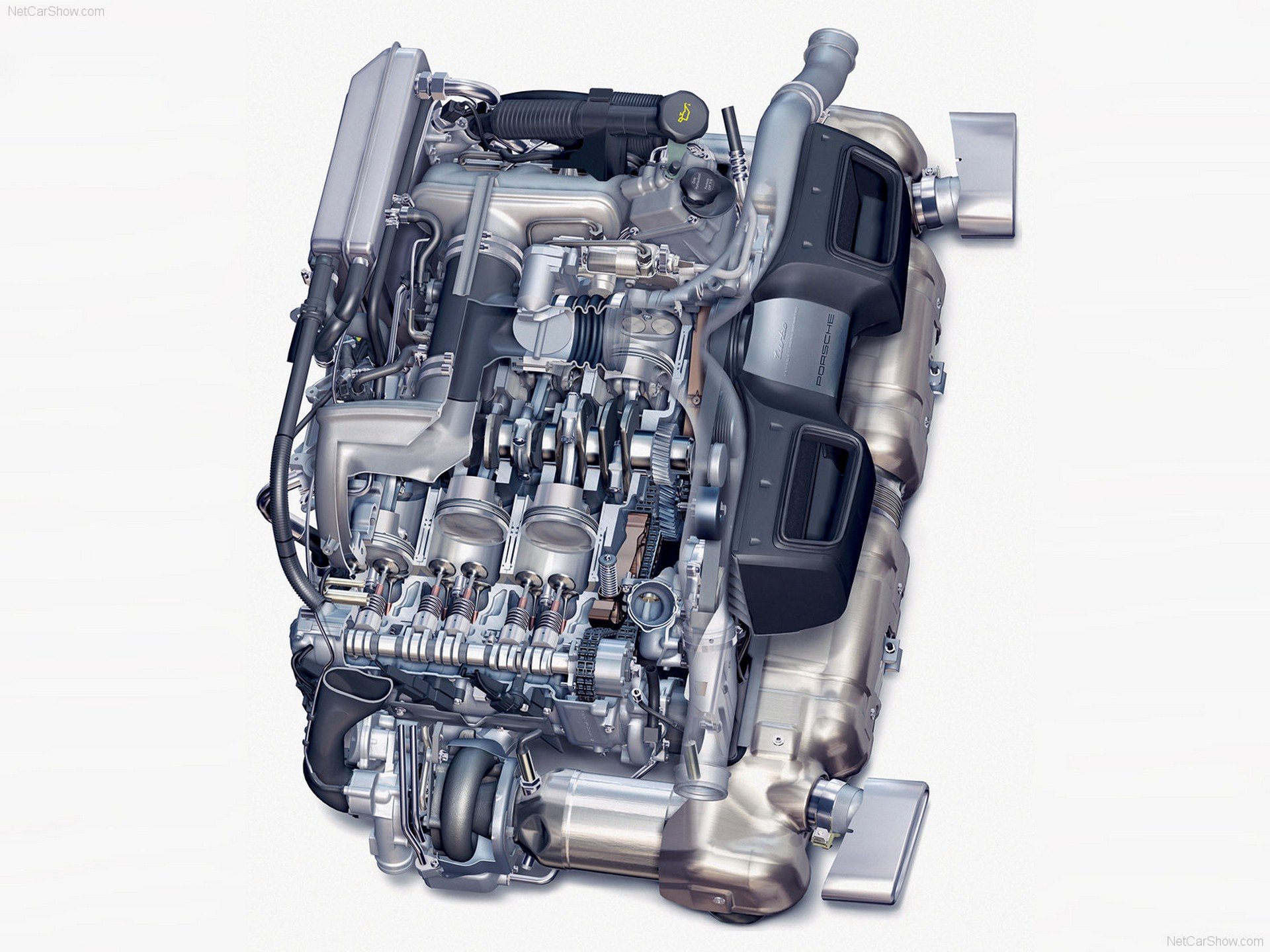

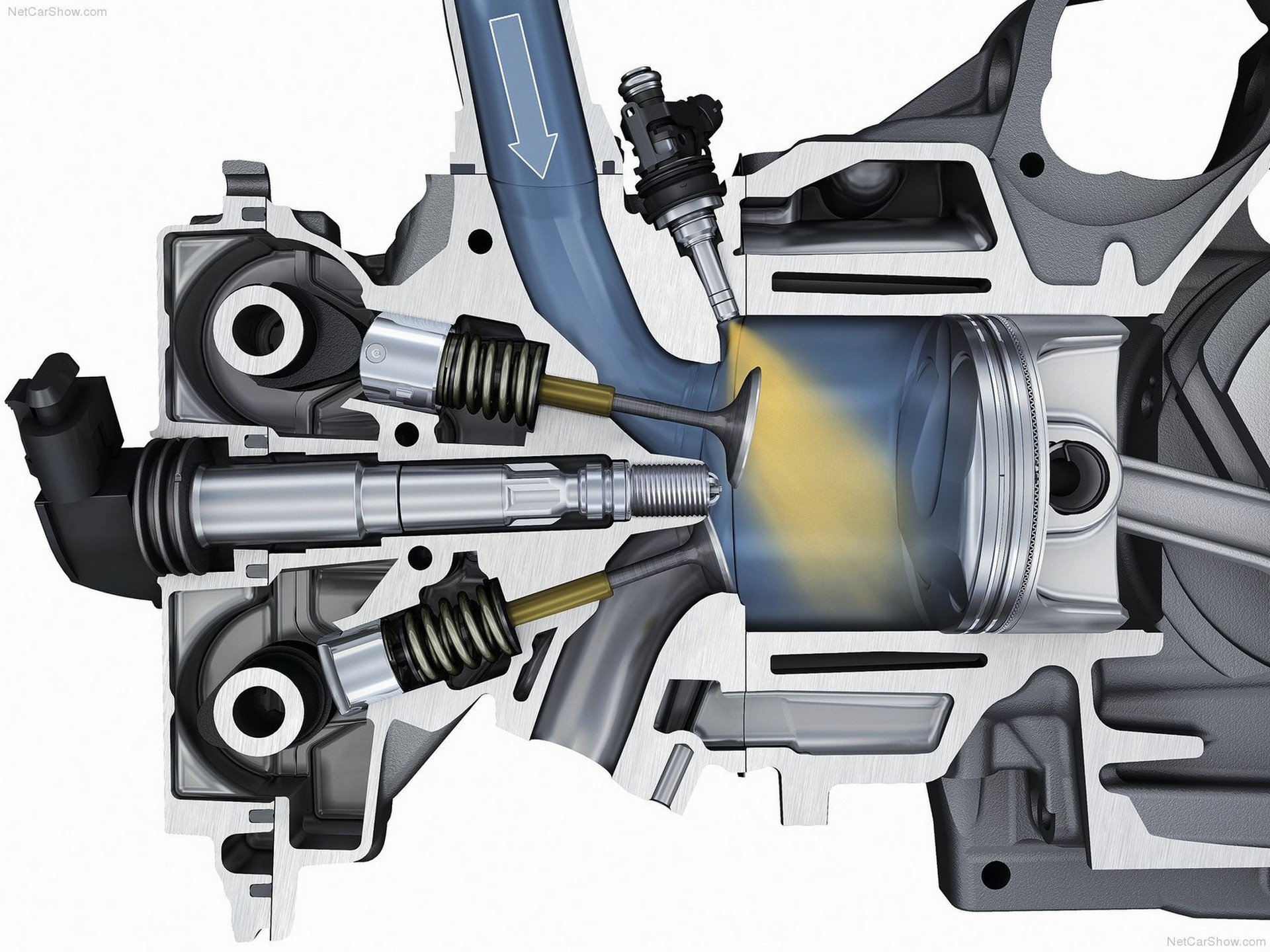

The rotating assembly—the pistons, connecting rods, and crankshaft—was forged for every model. The connecting rod bolt failures that occasionally occurred with the M96/M97 completely disappeared with the MA1. Fuel supply is the first direct fuel injection system in a road-going 911. The direct injection system, called DFI, was a step forward for power production, carbon emissions, and fuel economy. Compression ratios increased, leading to a bigger bang and more power from combustion. The accuracy at which the DFI provided the fuel allowed for a more accurate and efficient burn and produced less carbon-based emissions than its port-injected predecessor. The injection system required an all-new cylinder head with radically different ports than the M96/M97 and bespoke camshafts to the S and non-S models. However, the most significant improvements came from the cylinder head castings.

The M96/M97 used a single casting and split the timing chain system across the front and back of the engine. However, the MA1 uses individual castings, allowing the chains to be at the front of the engine. The biggest benefit is the elimination of the dreaded IMS bearing. The IMS bearing failure, among other things, causes the valves in that head to go wildly out of time and come in contact with the pistons. Without the need for that IMS bearing, all the issues surrounding it no longer exist.

MA1.02 - 2009-2011 Carrera, Carrera 4, Targa 4

The base Carreras used the smallest MA1 in the 911 lineup. At 3.6L, it uses a different bore and stroke from every other MA1 fitted to a 911 and the smallest cylinder heads and camshafts. It was a significant step up from the M96.05 in the previous 997.1 Carrera, with its lack of IMS bearing issues and DFI for increased efficiency.

MA1.01 - 2009-2011 Carrera S, Carrera 4S, Targa 4S

The S models use the MA1 designated .01. It uses a shorter stroke and a larger bore to achieve its 3.8-liters of displacement. The non-S models share the cylinder head port design, though the S uses unique camshafts. Power levels increased to around the 997.1 Powerkit’s performance, making it a decent bump over the 997.1 Carrera S.

MA1.01S - 2010-2011 Carrera GTS

The 997.2 Carrera GTS is fitted with a modified version of the engine found in the Carrera S. Porsche changed the cylinder heads and added a freer-flowing sports exhaust, a “variable resonance” intake manifold, a carbon airbox top, and a revised engine map. This engine was available in the Carrera S/4S with the X51 Powerkit option. Torque remained the same but came on lower in the rev range. Horsepower saw a considerable bump, with significantly more power under the curve above 6500 rpm. Every MA1.01S also uses a deeper oil sump with increased baffling for better oiling on the track.

MA1.70 - 2009-2013 Turbo

The facelifted Turbo received the new direct-injected engine, leaving behind the legendary Mezger-based unit. It shared all of the improvements of the normally aspirated cars and kept the reliability of its predecessor. The new mill jumped to 3.8L thanks to a larger bore and stroke. The direct fuel injection allowed Porsche to raise compression and lower the peak boost level, helping the MA1.70 make another twenty horsepower under less stress. The increased compression and lower boost level also improved fuel consumption. The VTG turbocharger design was carried over to the new engines, as was the GT2’s “expansion” intake manifold.

MA1.70S - 2009-2013 Turbo S

Porsche resurrected the Turbo S for the latter half of the 997’s production. Among suspension and equipment differences, the Turbo S gained some power. Displacement stayed the same, as did the general spec of the engine. A 0.2 Bar bump in peak boost pressure and some remapped engine parameters for fueling and valve control gave the Turbo S a thirty-horsepower bump.

M97.77 - 2010-2012 GT3

The M97.77 was an evolution of its predecessor found in the 997.1 GT3. A 2.7mm increase in bore raised the total displacement to 3.8L, keeping the engine in line with the rest of the lineup. The decision for the increase was simple: the GT3R and RSR would benefit from a larger engine, so the road cars received them for homologation purposes. Updates over the preceding engine included the larger displacement and a new VarioCam system extending to the exhaust camshafts. Power and torque saw their peaks rise by around twenty.

M97.77R - 2010-2012 GT3RS

The GT3RS received more power than the GT3 for the first time. Slightly higher compression and some revised intake bits lent to a horsepower bump. Displacement is identical to the GT3.

M97.74 - 2012 GT3RS 4.0

The last 997 GT3RS variant was a 500-unit run of the GT3RS 4.0. It’s Porsche’s last Mezger-based engine, capping off the nearly twenty-year run of the water-cooled/air-cooled hybrid. The engine case, crankshaft, and connecting rods are directly from the GT3R and RSR race cars. The cylinder heads have unique ports for better flow, and the intake manifold is thinner and lighter with wider and shorter runners. Bespoke catalytic converters and air filters manage the increased airflow requirements. It was the closest thing anyone could get to a definitive race car engine in a road car.

M97.70R - 2010 GT2RS

With the future of the GT2 in question, Porsche developed the GT2RS as a possible last hurrah. The engine was based on the unit from the GT2 and carried the same 3.6-liter displacement. Porsche upped the boost by 0.2 Bar, remapped the VarioCam Plus system, and fitted larger intercoolers to increase performance. All of those Improvements added up to a ninety horsepower bump over the GT2 and the most powerful engine ever fitted to a 911 at the time.

Porsche M96.05/M97 Common Faults

As the M96.05 and M97 engines are essentially carryovers from the 996, their common issues remain mostly the same. That said, the frequency at which they appear is generally less than the 996. Plan to take care of a few of these things throughout the life of a 997.

Intermediate Shaft (IMS) Bearing

The IMS bearing failures affected enough 996s to cause a stir in the Porsche community and give the 996 a reputation for blowing up. Porsche took the engine issues seriously and gave the 997 two updated engines—er, mostly. The early M96.05 in the base Carreras—up to engine number 6950745— still used the serviceable 996 bearing. Problems are a bit less frequent than the 996, but they do still happen.

The M97 in the S models rarely have failures, but they have occurred enough for owners to take notice. Their bearing is the largest of the group, but unlike the early style, they aren't serviceable with the engine together. Servicing the bearing means opening the engine case, making the process significantly more involved and costly. Consult the service records on any 997.1 non-Mezger engine and understand that an IMS bearing service or replacement may be in the future.

Cylinder Bore Scoring

Although the IMS bearing is the flashy failure that the internet has morphed out of proportion, this is what they ought to be worried about. Cylinder bore scoring is a death knell for the engine or your wallet as it requires significant repair if not complete replacement. Repair is preferred because replacing the engine with another one, rebuilt as stock or not, doesn’t solve the issue.

Bore scoring happens when an uncoated piston skirt wears against the LokaSil cylinder wall. The M96/M97 piston skirt wears an iron coating, and whether due to the different expansion rates provided by the cylinder walls and forged pistons or through a funky rod-to-stroke ratio, it flakes off at the bottom of the piston stroke as the skirt peaks out of the bore. Uncoated piston skirts then contact the cylinder walls and gouge them, letting oil by, ruining the piston-to-wall clearance, and destroying the cylinder. It’s a significant issue, and it’ll make itself apparent through one or more of these symptoms:

- Loud tick/knock from the affected cylinder

- Increase in oil consumption

- Sooty tailpipes

- Soot in the engine oil

- Oily/sooty bumper cover

- Cylinder misfires

This issue affects all 3.4L, 3.6L, and 3.8L non-Mezger M96 and M97 engines. The only guaranteed fix is to send the engine case off to have the original cylinders removed and replaced by a more traditional cylinder liner and piston. It’s a significantly costly endeavor—upwards of $17,000 done correctly—but the results are a bulletproofed engine proven free of any future issues.

Coolant Pipe Failure

The Mezger-based engines use water-cooled cylinders and heads, while the crankcase is cooled only by oil. The coolant pipes that distribute the coolant across the heads use an adhesive to secure the pipe ends into the main pipe assembly. Over time, the glue breaks down and loses its hold, causing coolant to leak out. In extreme cases, when the leak develops, the pipe ends can shoot out of the pipes, causing a rapid loss of coolant and a huge steamy mess.

There are a few remedies for the coolant pipes that all involve securing the pipe ends into the pipes by way of a screw or bolt. Servicing and repair usually require engine removal, though some shops have figured out how to keep the engine in the car during repair. Consult a local Porsche dealership or independent shop to get an estimate on repairs. If you plan on tracking your Mezger-based engine, several event hosts require the coolant pipes to be secure before letting you into an event, making it a must-have modification.

Variocam Solenoid

The VarioCam system is Porsche’s variable valve timing. Adjustable intake camshaft sprockets and various sensors connect the camshafts to the engine computer. The computer can then activate solenoids that allow the position of the sprockets to change and adjust when the valves open or close to the desired level of performance. The solenoid can fail electronically or get clogged by lightly dirty oil, causing it to move less than required or be completely stuck. They will cause a rough idle and a lack of power. The engine computer will quickly notice the failing solenoid and trigger a warning light.

Air Oil Separator

The air/oil separator (AOS) pulls oil vapors and pressure from the crankcase and sends them through the intake manifold. The vacuum supplied by the AOS also helps to seal the low-tension piston rings. Failure of this part allows excess oil to flow through the intake and be burned during combustion, leading to oil consumption and misfires from fouled spark plugs. The entire air/oil separator system should be considered a maintenance item and periodically replaced.

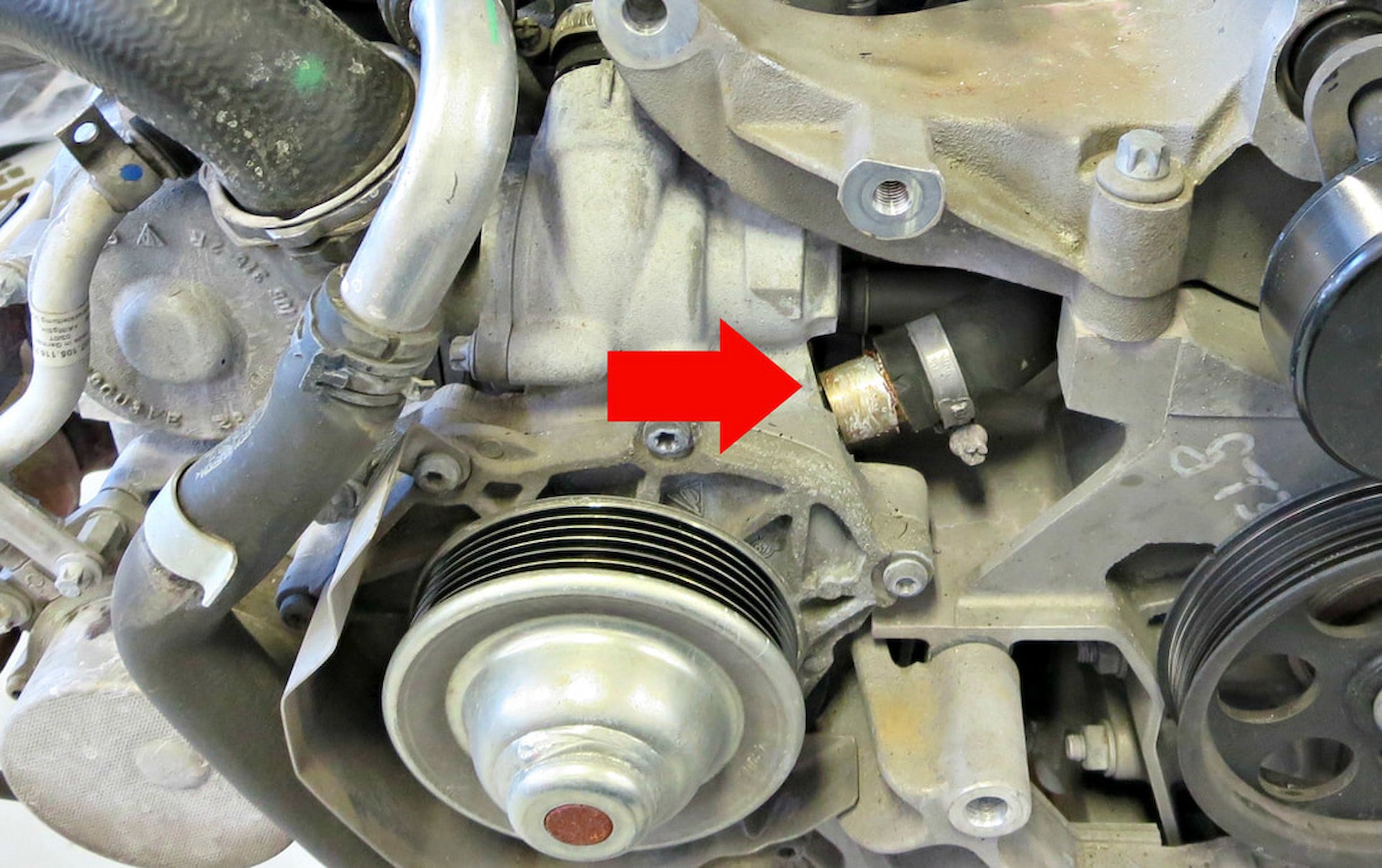

Water Pump

The water pump installed at the factory uses a plastic impeller to drive the coolant through the engine. Owners have seen those impellers break apart and get sent through the engine, clogging coolant passages and the thermostat. If not replaced on schedule, the pump will fail, allowing the impeller to contact the engine block, damaging it, and sending impeller bits through the engine again.

Upgrading to a water pump with a metal impeller is the best way to prevent plastic from being sent through the engine. However, replacing the water pump at the recommended interval is the only way to prevent extra damage. Regardless of which type of water pump you choose, replace it every 3-4 years as preventative maintenance.

Expansion Tank Cracks/Caps

The expansion tanks on almost every modern engine are plastic. While cheap and light, the constant exposure to heat in the engine bay will cause the plastic to become brittle and crack. They are inexpensive to replace but require a full cooling system bleed, prolonging the replacement process significantly. The expansion tank cap seals can also fail over time. They are inexpensive to replace and have been updated by Porsche, preventing further issues.

Starter Cable

The starter or alternator cable on the 997 engines can build up resistance to a poor or weakening crimp. The main symptom is a slow or sluggish start while the car is fully up to temperature. Parts aren’t too expensive, but a replacement will be fiddly.

Rear Main Seal

While several of the 996’s engine issues were addressed, oil leaks from the rear main seal weren’t. The rear main seal seals the crankshaft to the engine case, and when installed improperly or weakened over time, they will allow oil to pass by. Bad leaks can get oil onto the clutch assembly, potentially ruining parts. They require a transmission and flywheel removal for service, so replacement costs can get expensive.

Porsche MA1 Common Faults

Bore Scoring

This is only an issue for the DFI 997.2s in cold climates. The MA1 was built to very tight tolerances and requires a sufficient warm-up before strenuous driving. Cold temperatures cause the engine clearances to shrink, requiring an extended warmup. Most owners were unaware and ended up causing damage by revving the engine too high before the clearances were in spec. Whether it was a lack of silicon coating on the cylinder or the piston-to-wall clearances weren’t up to spec, a scored cylinder is an engine killer. Repairs will be expensive and can require a new engine. If you’re in a cold climate, let the engine come up to temperature through driving before exceeding around 3000RPM.

Porsche M96.05/M97 Maintenance Schedule

The following service schedule is taken directly from Porsche, although we may recommend more frequent service as preventative maintenance and extra peace of mind for some items.

Oil Changes

Porsche stated an oil change interval of 20,000 miles or every two years. We do not recommend you follow that. Instead, an oil change every 5,000 to 7,500 miles with synthetic oil will be much healthier for any 997.1 engine. 997s that don’t hit the mileage annually should have their oil changed once a year. For example, those who live in exceptionally dusty areas should have more frequent changes.

Major Maintenance

After 36,000, 72,000, 108,000, 144,000 miles etc. / 60,000, 120,000, 180,000, 240,000 km etc.

Note: If the mileage for scheduled maintenance is not reached, major maintenance must be performed at 3, 6, 9, or 12 years.

❏ Coolant hoses: Check condition

❏ Radiators and air intakes: Visual inspection for external debris and blockage

❏ Coolant: Check level and antifreeze

❏ Air filter: Replace filter element

❏ Pollen filter: Replace filter element

❏ Fuel lines and connections: Visual inspection for damage and leaks

❏ Exhaust system: Visual inspection for leaks and damage; check mounting and heat shields

❏ Battery: Check condition and electrolyte level

Additional Maintenance for Spark Plugs (Except Turbo)

❏ Replace spark plugs every 36,000 miles (60,000 km) or every four years

Additional Maintenance for spark plugs (911 Turbo 997.1 only)

❏ Replace spark plugs every 24,000 miles (40,000 km) or every four years

Additional Maintenance for the Drive Belt

❏ Check the drive belt at 36,000 miles (60,000 km) or every four years

❏ Check the drive belt at 84,000 miles (140,000 km) or every ten years

❏ Check the drive belt at 132,000 miles (220,000 km) or every 16 years

Additional Maintenance 48,000 miles (80,000 km) or every six years

❏ Replace drive belt

❏ Replace fuel filter (Turbo only)

Porsche 997.2 Maintenance Schedule

The normally aspirated MA1 engines have a separate maintenance schedule from the other models, as do the Turbo and GT cars. Typically, we recommend following the manufacturer’s instructions, but you can shorten some intervals for peace of mind.

Oil Changes

Porsche stated an oil change interval of 10,000 miles or once a year. Generally speaking, this interval is on the longer side. Modern synthetics can last that long, but we’d recommend a maximum of 7,500 miles, especially if the engine sees regular spirited driving and trips to redline. 997.2s in excessively dusty or sandy climates could benefit from a slightly shorter service interval.

Maintenance

After 20,000, 60,000, 100,000, 140,000 miles (30,000, 90,000, 150,000, 210,000 km)

(Carreras Only)

After 12,000, 36,000, 60,000, 84,000 miles (20,000, 60,000, 100,000, 140,000 km).

(GT3 Only)

After 40,000, 80,000, 120,000, 180,000 miles (60,000, 120,000, 180,000, 240,000 km)

(Turbo Only)

Note: If the mileage for scheduled maintenance is not reached, intermediate maintenance must be performed no later than after two, six, and ten years

❏ Coolant hoses: Check condition

❏ Radiators and air intakes: Visual inspection for external debris and blockage

❏ Coolant: Check level and antifreeze protection level

❏ Pollen filter: Replace filter element

❏ Battery: Check condition and electrolyte level

❏ Electrical equipment, warning, and indicator lights: Check function

Additional Maintenance for Spark Plugs

❏ Replace spark plugs every 24,000 miles (40,000 km) or every four years (GT3)

❏ Replace spark plugs every 30,000 miles (65,000 km) or every four years (Turbo)

❏ Replace spark plugs every 40,000 miles (60,000 km) or every four years (Carrera)

Additional Maintenance for Drive Belt Inspection

For All Models

❏ Check drive belt at 40,000 miles (60,000 km) or every four years

❏ Check drive belt at 100,000 miles (150,000 km) or every ten years

❏ Check drive belt at 160,000 miles (240,000 km) or every 16 years

Additional Maintenance Drive Belt Replacement

Turbo and Carrera

❏ Replace drive belt every 60,000 miles (90,000 km) or every six years

GT3

❏ Replace drive belt every 48,000 miles (80,000 km) or every six years

M97 Performance & Reliability Upgrades for the Street

The M96 engine can be more reliable for the street with routine maintenance and adding a few upgrades. If you’ve just picked up a 997 or have owned one for years and want to improve, here’s what you will need.

Air/Oil Separator with Hoses (V450081KT, V450081KT1, V450082KT, 996BREATHERKT)

The air/oil separator relieves crankcase pressure by drawing the oil vapors into the intake stream to be burned through the engine during combustion. The separator and hoses are plastic, and like any other plastic component found near heat, it is prone to degradation and cracking. When this happens, you’ll have a vacuum leak and, potentially, a misfire code. The air/or separator diaphragm can also fail, sucking oil into the intake in the process. Oil consumption, rough idle, and blue exhaust smoke indicate a failing AOS.

Spark Plugs and Ignition Coils (997IGNCLKT)

Spark plugs need replacing every 30,000 miles. While they can sometimes last longer, the ignition coils are prone to cracking due to their position in the engine bay and proximity to the exhaust. That cracking will lead to misfires and driveability issues. It’s best to replace both the spark plugs and ignition coils together.

Water Pump with Metal Impeller (PA1152KT1)

The water pump on the M96 engine is a maintenance item, and we recommend replacement every 3-4 years, regardless of which type of water pump is in use. The factory water pump came with a composite impeller known for cracking and breaking. A water pump failure can prevent coolant from circulating throughout the engine, causing it to overheat. It can also circulate the bits of plastic that break off throughout the engine, and they can clog the coolant passages, leading to the engine overheating. A metal impeller water pump can prevent these failures, add reliability to your cooling system, and save your engine from catastrophic damage.

CSF Radiators (997 Carrera)

The end caps on the factory radiators are plastic and crimped onto the aluminum core. They are another area where the plastic will weaken over time through thousands of heat cycles and eventually crack and leak coolant. CSF radiators are a full aluminum construction with aluminum end tanks. They also have a larger double-row core, which helps increase both cooling capacity and cooling efficiency, a must-have upgrade for any 911 seeing aggressive street use.

LN Engineering Magnetic Drain Plug (106-07)

A magnetic drain plug will keep metal debris and shavings from circulating throughout the engine, accelerating wear on critical components. The plug can also help detect significant engine wear or problems; if you notice a lot of metal collecting on the magnet when you remove it for oil changes, there is probably an issue. A used oil analysis in conjunction with a magnetic drain plug will help notify you of any possible problems related to the health of your engine.

LN Engineering IMS Bearing Retrofit Kit (106-08.4, 106-08.2.2)

The IMS Bearing Retrofit Kit replaces the factory IMS steel ball bearing with a ceramic hybrid ball bearing. The kit's improved bearing and other components add strength and reliability to this sensitive engine area. Service requirements for the IMS Retrofit kit are every six years or 75,000 miles. Consider this upgrade if your M96 or M97 engine comes without IMS documentation.

LN Engineering Chromoly Engine Oil Pump Hex Drive (106-11)

The factory oil pump drive is a mild-steel, non-heat treated drive that can easily break apart and fail on any engine driven hard. Upgrading the oil pump drive with a Chromoly heat-treated version from LN Engineering is a low-cost upgrade for street and track cars.

LN Engineering Oil Sump Kit (106-00)

The M96 engine uses an integrated dry-sump system. Unlike the air-cooled engine with a separate dry-sump oil tank, Porsche cast the oil tank directly into the bottom of the M96 engine case. It was great for packaging but led to oil starvation issues when pushed hard. Any 996 seeing track time should utilize the upgrades to the oil sump and oil pump. Ensure your oil level is always at the high mark if you’re using the factory sump plate to help prevent oil starvation.

The oil sump LN Engineering kit provides an additional half quart of oil to the crankcase while lowering the oil pan by a quarter of an inch. That reduces crankcase windage, oil consumption, and air/oil separator load. It’s an often-overlooked upgrade for owners who drive their 911 daily and enjoy spirited drives.

M97 Track Performance & Reliability Upgrades

The same parts used to bolster a street-driven engine don’t include those needed to go racing. Constant high-RPM usage puts a different strain on the engine than normal driving, something the M96 and M97 weren’t necessarily built for. However, with these upgrades, you shouldn’t have to worry about something failing because of a lack of durability.

CP Carrillo Connecting Rods (99603>-65590H, 996>-65708H)

If you are rebuilding your M96 engine for the track, one area to pay close attention to is the connecting rods. The issue is that the factory connecting rod bolts cannot withstand the engine load placed on them at the high end of the RPM range. That usage causes the rod bolts to stretch beyond their capacity, and eventually, they will become loose or break, leading to engine damage or complete failure. The CP Carrillo connecting rods offer a stronger, lighter-weight rod and stronger bolts that will add reliability and strength to your engine.

Motorsport Air/Oil Separator (99610792600)

The motorsport air/oil separator upgrades the factory unit and helps prevent oil from entering the intake when on the track. This part requires modifications for installation.

LN Engineering Deep Sump Oil Pan Kit (106-00.1)

The deep-sump oil-pan upgrade kit adds 2.0 quarts of additional oil capacity to your engine, helping in a couple of ways. First, it lowers the oil level in the crankcase so it doesn’t get aerated. Second, the included windage tray prevents oil from sloshing around during corning. The X51-style baffle keeps the oil from moving away from the oil pickup tube, preventing oil starvation. Upgrading the pan and baffling is the easiest way to ensure a constant healthy oil pressure on the race track.

LN Engineering Aluminum Timing Chain Tensioner Guide (106-10)

As you may have noticed by now, there is a theme with all of the failure-prone plastic engine components used in the M96 engine, and the timing chain tensioner guide is no different. The LN Engineering timing chain tensioner guide replaces the factory plastic guide and pressure pin with a billet aluminum guide and steel pressure pin. It also comes with a new guide pad, which is replaceable separately.

LN Engineering IMS Solution Kit (106-08.20, 106-08.40)

The IMS Solution Kit by LN Engineering is the ultimate solution to IMS problems and maintenance. This kit replaces the factory IMS ball bearing with an oil-pressure-fed plain bearing that requires no future servicing or replacement. This bearing is designed to last the engine’s life and is a must-have for track cars and streetcars. By resolving what is quite possibly the weakest point in the engine, you are free to focus your time and effort on driving, knowing you have the most durable and reliable IMS replacement on the market

MA1 Engine Performance & Reliability Upgrades

CSF Radiators (997.2 Carrera, 997.2 Turbo)

The end caps on the factory radiators are plastic and crimped onto the aluminum core. They are another area where the plastic will weaken over time through thousands of heat cycles and eventually crack and leak coolant. CSF radiators are a complete aluminum construction with aluminum end tanks. They also have a larger double-row core, which helps increase cooling capacity and efficiency, a must-have upgrade for any 911 seeing track use.

Porsche 997 Engine FAQ

What Is A Mezger Engine?

Hans Mezger was the engineer and designer behind the original air-cooled 911 engine. He had his hands in every performance and motorsport engine that came out of Porsche until he retired from Porsche in 1993. The Porsche 956 and 962 race cars of the 1980s used the air-cooled crankcase, the most central part of the engine, around which everything else is built, and its components with water-cooled cylinders and cylinder heads. The hybrid design held over 1000 hp for short periods and about 700 hp for over 24 hours.

Over the years, that engine design was revised to obliterate the competition and eventually made its way into the 996 and 997 Turbos and GT models. While not exactly the same as the engine found in those Le Mans-winning race cars, Hans Mezger’s basic design remained the same. The “Mezger” engines are in every 996 and 997 GT model and the 996 and 997.1 Turbo models. They are incredibly robust and have only one flaw: their coolant pipes. Once that issue is resolved, the “Mezger” engines are bulletproof.