When you first glance at any car, you see, well, a car, but if you scratch the surface of that visual and dig in a little deeper, you’ll also notice the complex system within it, composed of thousands of moving parts, all working together, in harmony. Many of these components are parts of subsystems, cohesively working together to achieve the one task they were designed to do. One such subsystem, the brake system, holds one of the most important safety features in the vehicle: the brake pads.

Sure, brake pads are a common maintenance item, but they surprisingly go overlooked way too often by vehicle owners. Aside from being a regular maintenance item, as mentioned earlier, brake pads are a vital component to your safety. Realistically, as large and complex as your vehicle is it’s hard to imagine the only thing that brings your vehicle to a safe stop, each and every time you drive it, is something as simple as a brake pad. But this small piece of equipment is what creates the friction against the surface of your brake rotor (or brake drum). It produces the much needed stopping power.

One of the most common questions we get at FCP, regarding brake pads, is “which ones work best for my car?” If you read a bit further, we will do our best to not only answer this question for you, but would like to give you, the driver, a little history while we’re at it.

History

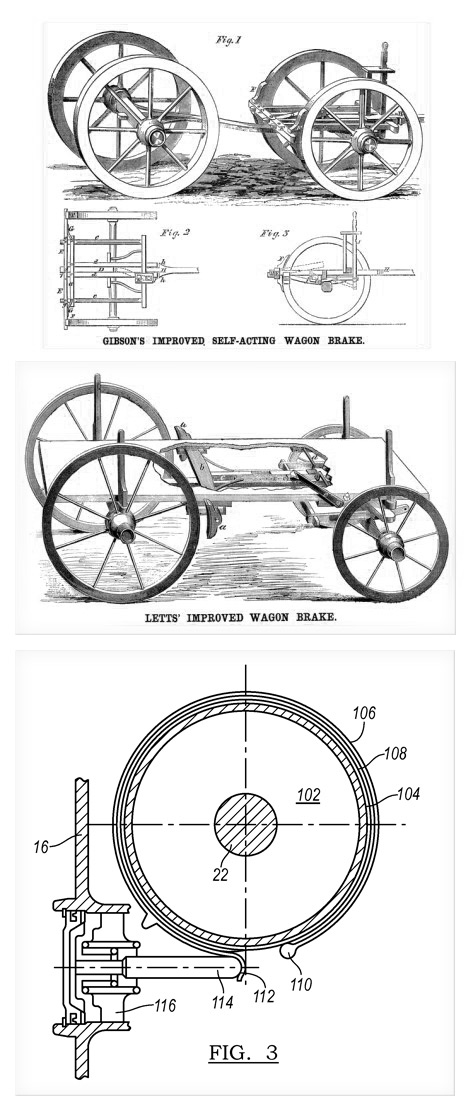

Basically, automobile braking technology has come a long way in the last 100 years. At FCP, we think it’s important to acknowledge and respect our vehicle’s history. That being said, the first braking system for an actual vehicle with wheels was initially put to the test on horse drawn carriages. These brake systems became necessary due to the fact that horse drawn carriages could get up to pretty high speeds, but the horse itself wasn’t capable of stopping the moving carriage on its own. Sound similar to how our modern day cars work, right?

This elementary braking system used a simple hand lever. It would press a wooden block wrapped in leather against the inside of the wheel. We know what you’re thinking; this sounds a bit sketchy. Well, you’re right. And usually, these braking systems were not effective at all in wet weather. Also, this aforementioned braking system was used on some of the first self-powered cars, but as the speed of these cars progressed over time during the turn of the 20th century, so did the need for better braking systems. And the “modern” braking system began to take shape.

The first modern brake system was similar to what you would see on a car today, but with a slightly simpler design. This brake system used iron rotors with copper brake pads. Yes, they were extremely noisy. This is why this system never gained popularity during this time period.

In 1899, Gottlieb Daimler created an external band brake which used steel cables wrapped around the outside of the brake drum. This would “stretch” when the hand brake lever was pulled. The cables would stretch on a system of levers inside the drum and in turn would bring the vehicle to a stop. This system became known as a band brake. One of the down sides to this system was not being able to confidently utilize these brakes on hills. The hand brake also had issues in wet weather when the friction material used would not bite down properly. This system also ended up suffering from corrosion and needed constant maintenance, making it too costly.

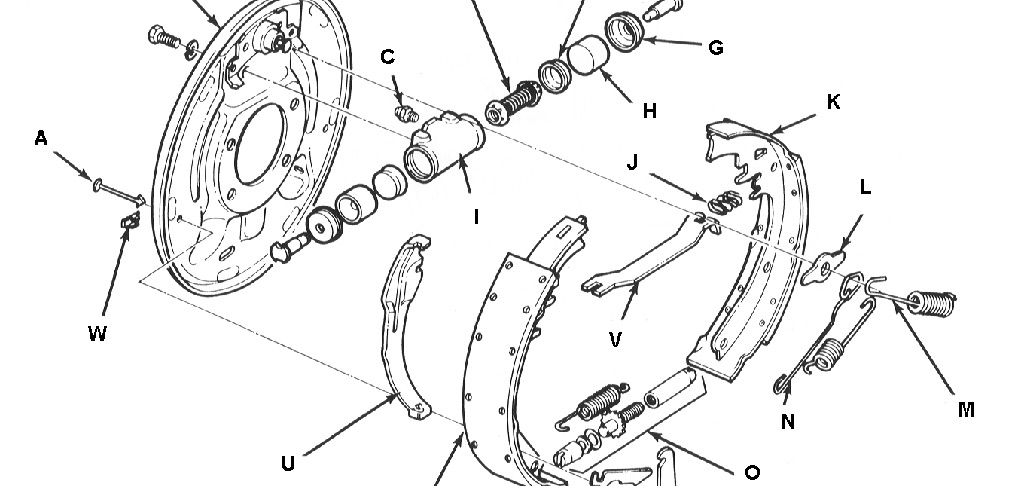

In 1902, Renault, patented a new type of drum brake system. This new style of drum brakes kept the otter drum design and changed the internals to a new braking material. It used semicircular pads, which would press against the inside of the drum. In turn, this system proved to be much more efficient, safer to operate in wet weather, and more durable. The brake pads in this system could last 1 to 2 thousand kilometers, before service and helped reduce operating costs. So in turn, this drum brake system became the dominant braking system on passenger cars, up until the 1950’s and 1960’s, when point disc brakes, as you see on today’s vehicles, became the standard. Those, of course, could be attributed to E.A. Sperry, who was likely the first to invent a disk braking system when he used them on his 1898 electric car.

The reasons behind this switch are simple: cars became capable of attaining higher speeds and drum brakes were not as effective at these higher speeds. Disc brakes, originally used on race cars and aircraft, work fundamentally in the opposite way as drum brakes do. Drum brakes have friction material pressed against the inside of a drum, while disc brakes have friction material pressed against the outside of the rotor. The main advantage with this system is that it cools drastically better than drum brakes. Also, a disc brake has two friction surfaces as opposed to one, allowing for a much more improved performance. Additionally, this system is what allows modern vehicles to execute traction control and ABS.

After recapping some history on vehicle braking systems, we thank you for allowing us to “nerd out” a little bit, but we can’t help it, our team at FCP lives and breathes this stuff. We love our car, your car, and… Well, we love cars. All cars. So, thank you for humoring and possibly learning a little more about your vehicle history with us. We feel that it’s important to understand the past history of this technology, so you can better understand the future of it.

Brakes Today

At this point, let’s discuss the two most common types of brake pads on the market and how they affect our vehicles braking systems. But keep in mind; there are several thousand variables that affect your vehicle’s braking performance. There are several factors that you should keep in mind when choosing brake pads. These factors are what you demand as a driver and directly affect how you will be choosing to use your vehicle. So, the first thing you need to do is ask yourself how you will be using your vehicle. So here's some questions to consider:

- Do you just use your car daily to get to and from work?

- Do you drive your car gently?

- Do you demand higher than average performance from your vehicle?

This list of questions can go on and on, so in the interest of saving space and time we have learned that most drivers fall into two particular categories:

The Daily driver

The daily driver uses their car to get to and from work and to run errands. They need their vehicle to be reliable and predictable at all times. Many of us refer to these drivers as, “A to B” drivers. These are the most common.

Performance driver

The performance driver focuses their driving and vehicle on straight up performance. They need and demand their car to be able to stop repeatedly under extreme conditions. Also, and just as important, they need this vehicle to be reliable and predictable, under extreme conditions.

Now, it’s possible to have both of the categories above cross with each other and we find that they can. Keeping your needs and wants clear when choosing a brake pad is going to make the selection process much simpler. In the auto market today, there are two main types of brake pads available for the average consumer.

What are Brake Pads Made Of?

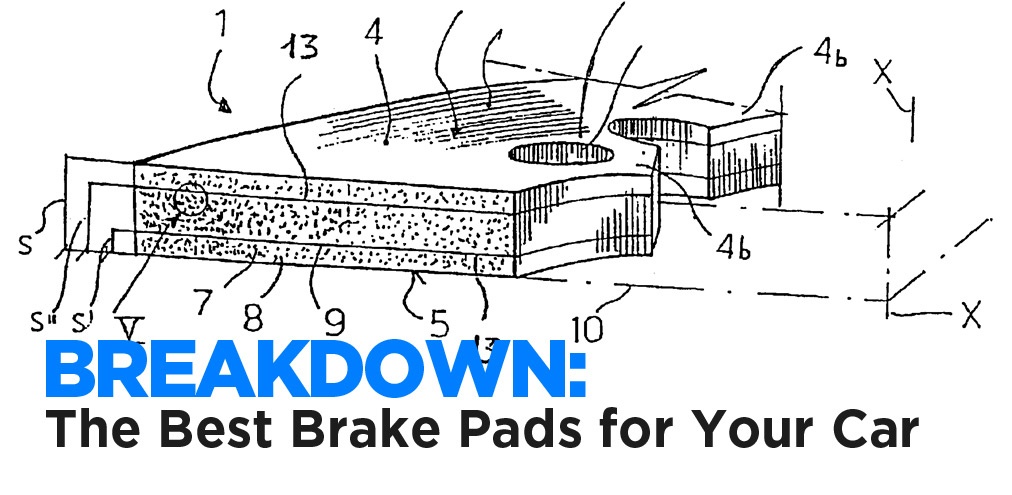

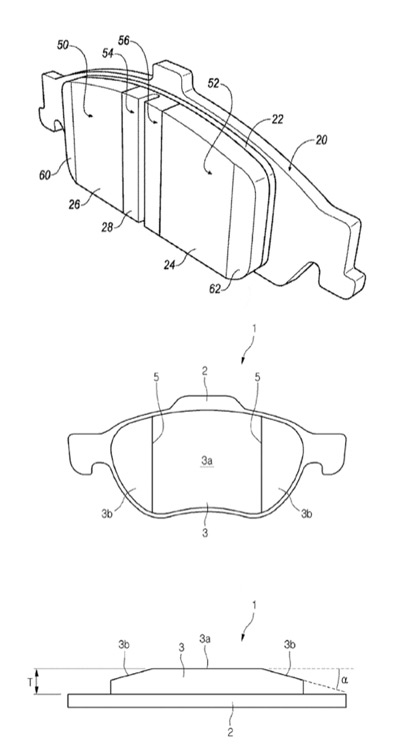

Put plainly, brake pads are simple. They are composed of a friction material pad backed by a steel plate. The composition of the friction material is equal parts science and art. There are pad manufacturers that have 50+ compounds covering an array of uses. Up until the early 1990’s, many brake pad friction materials were held together with an asbestos binder. When this material was changed, manufactures chose between organic, semi-metallic, and ceramic. When you see a pad description that states the material of the pad, it is actually referencing the binder of the friction material. The two most common brake pads on the market today are semi-metallic and ceramic.

Organic Brake Pads

The first type of pad material we will touch on is, organic pads. Put simply, an organic pad must have less than 20% metallic content. One of the main benefits of an organic brake pad is a quiet operation and greatly improved rotor life, since it’s not as abrasive. Because organic pads are softer, they have a shorter service life and do not perform well under high operating temperatures. This makes them unsuitable for towing or high performance applications. Some of the high-end organic pads can be on par with some lower quality semi-metallic pads without the excessive rotor wear. FCP typically recommends that these pads be restricted to daily driven vehicles only. We even will recommend not using them for some vehicles, like, trucks, SUV’s, and high performance vehicles.

Semi-Metallic Brake Pads

Semi-metallic pads are the most common type of brake pad installed on cars from the factory. You will understand why, shortly. Semi-metallic pads are comprised of a hard resin with steel fibers. This mixture helps increase the hardness of the pad, as well as to promote extended pad life. The single biggest advantage of semi-metallic pads is their high temperature performance. Believe it or not, semi-metallic pads actually gain grip as they get to their initial operating temperature. This single characteristic makes these semi-metallic pads ideal for vehicles that have a higher braking demand and operating temperature. Vehicles that demand higher than normal performance from their brakes can include vehicles used for towing and racing. Under these types of conditions, brake friction creates extremely hot temperatures. This is why it is critical to use a pad that will grip well at this level.

There are some semi-metallic pad disadvantages. These should be taken into consideration, as well. First off, metallic pads have a noisier operation than other types of pads. This is due primarily to the higher metal content in the brake pad rubbing against the surface of the rotor. Semi-metallic pads also wear down the surface of rotors faster as the pad material is harder than the rotor. These pads also can be a bit dirtier than average and can leave a lot of brake dust on your wheels after a lot of driving.

One major consideration to keep in mind when choosing a semi-metallic brake pad for a high performance application (non-street use or towing duty), is both where and how you will be using your vehicle. As stated earlier, semi-metallic brake pads increase their performance as they get closer to their operating temperature. On the ultra-high performance end of the brake spectrum, you will need to take into account what your vehicles brake operating temperature range is. High performance brake pad manufactures, such as Hawk, publish their pads operating temperature ranges. Brake pads rated for higher heat ranges will offer amazing performance under these extreme demands, like racecars.

Because many of these cars endure such a heavy demand on their brake systems a brake pad that is designed for track use may not be suitable for street use, just as street driven cars (even high performance street cars) are incapable of generating the required braking heat for the pad to work correctly. For this reason, it is incredibly important to research and determine your braking needs before investing in a set of ultra-high performance brake pads.

Ceramic Brake Pads

The final pad material we’ll talk about here is ceramic. Ceramic pads are relatively new to the market and offer an interesting array of characteristics that fill in some of the gaps between metallic and organic pads. Ceramic pads use ceramic fibers as the binder for the friction material. Ceramic is a great pad material for street use, as it offers predictable bite characteristics and performance. This is especially the case at lower operating temperatures. This is also the category where 95% of street cars fall into place.

Ceramic pads offer consistent brake pedal feel, regardless of the temperature and these are both coefficients of friction. This means temperature changes do not affect them. Ceramic pads also benefit from a quiet, non-squeak operation, which also includes extremely low brake dust. Any visible brake dust is usually light and can be cleaned easily. Ceramic pads also have a relatively long lifespan. They aren’t too aggressive on rotor surfaces either, but some ceramic pads suffer from less initial bite or grab, which can get worse under high operating temperatures.

| Organic Pads | Semi-Metallic Pads | Ceramic Pads | |

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Application | Daily driven, light duty driving | High-horsepower street cars, or towing applications |

Daily driven vehicles, performance oriented |

Over the years, braking technology has come a long way. It’s gone from leather wrapped around a wooden block, like a bound book, to high tech materials and formulations backed by modern day science. At the end of the day, the only thing bringing your vehicle to a safe stop is the brake pads on your vehicle. You have several choices when it comes to the type of brake pad and we at FCP Euro hope that this guide makes the selection process a bit less intimidating for you. As always, if you have any questions feel free to email us at service@fcpeuro.com.