For 1975, U.S. buyers were privileged to an all new feature—emissions! Yes, the U.S. Environmental Protection Agency or EPA, required that all cars be fitted with an emissions system to hep curb exhaust pollutants. With the on set of the new government requirements, auto makers scrambled to get their cars into compliance and that made for a few problems.

Before we go further, here is a brief timeline on how the U.S. emissions laws evolved in the 1970’s and what was going to be required over a decade. In 1970, the United States Congress passes the first major Clean Air Act, requiring a 90 percent reduction in emissions from new automobiles by 1975. Congress also establishes the Environmental Protection Agency that same year, giving it broad responsibility for regulating motor vehicle pollution and the new standards manufactures must meet by 1975 and beyond. The EPA begins testing the fuel economy in 1971 and informing consumers about the importance of gas mileage of their vehicles. 1972-1973, brings about the exhaust gas recirculation valves that are developed as automakers strive to meet NOx (Nitrogen Oxides) standards.

The EPA designates new transportation controls in some of the nation’s largest cities, mandating exclusive bus and carpool lanes. Also in 1973, the EPA released a study confirming that lead from automobile exhaust posed a direct threat to public health and it was decided this same year to begin the phase out of leaded gasoline. For 1975, the U.S. Congress passes the Energy Policy Conservation Act, setting the first fuel economy goals for automakers. Launched too, was the Corporate Average Fuel Economy (CAFE) program mandating more stringent fuel economy beginning with 1975 model year vehicles. The "first generation" catalytic converters are added to cars in 1975, significantly reducing vehicle emissions. Unleaded gasoline is also introduced since lead in gasoline would cause failures to the catalytic converters. And in 1977, the U.S. Congress amends the Clean Air Act, which set a schedule for continued reductions in emissions from automobiles for decades to come. This information adapted from the EPA.gov.

Whether you take kindly or not to the EPA regulations, emissions systems are now a part of our more modern classics. Unfortunately too many are interested in stripping their cars of the early emission systems in hopes of more horsepower. While one might gain a few more ponies with out the system, under normal driving conditions the additional power will be undetectable.

So the questions remain, should I scrap the emissions system or restore it with the car. In my opinion, keeping the car as original as possible is always the best way to go and it keeps the car legal in this instance for a number of states. Even if your state does not require an emissions test or idle test, should you ever wish to sell your car to someone who lives in a state with classic car emissions requirements, your field of buyers and asking price will be greater. Furthermore, as more and more people modify classic vehicles, the fewer there will be that are as the factory built them and there is value in original.

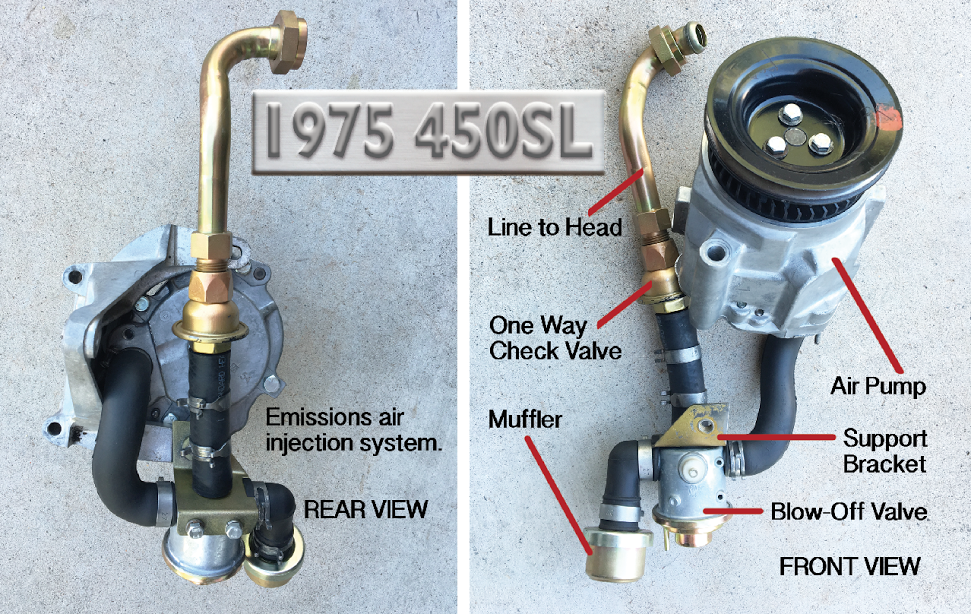

There are modifications however that can be done to enhance your experience and keep the emissions system in place. A great example is the 1975 Mercedes 450SL. The first 450SL to receive an emissions system. It should be noted that the catalytic converters are not the only piece of the puzzle. The 450SL was also equipped with an air pump or smog pump, that forced air in to the engine at various times to help the fuel combust more fully hence producing less tailpipe emissions.

PLENTY OF AIR INJECTION

This air pump however is also directly related to the cold start of the 1975 450SL and having a failed or removed system will effect how well the engine will run. If you own one of these great cars it is or will be quite evident that there are a fair number of hoses strung throughout the engine bay. These hoses comprise of both vacuum, air injection and vapor recovery from both the fuel tank and the crankcase. For now, we will focus specifically on the emissions system and the related components as shown in the marked photos.

As shown, the air injection system is not at all completed, but is deigned to pump or force air into the throttle body and cylinders. When removing the original components, it was quickly discovered that the 41 year old system was worth nothing more than scrap metal. The one way check valve was rusted through, the muffler dispensed a substance resembling baking soda, the metal air line was clogged solid and rusted through and the pump sounded like a coffee grinder when turned by hand. This could very well have been one of MANY reasons the car chugged when it was first started.

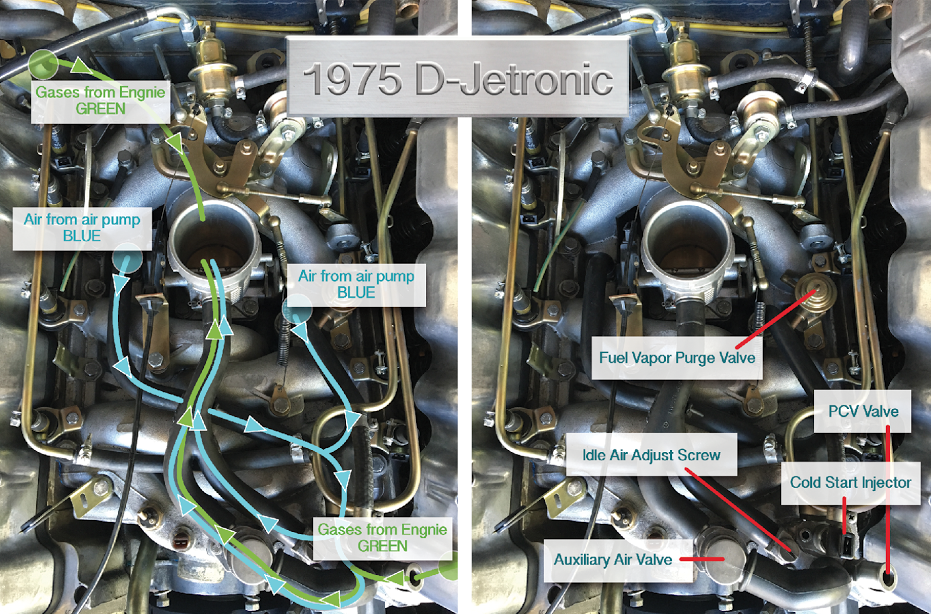

The images show a very general working of the over-all emissions system.

The left image shows how the emissions air pump delivers air throughout the system indicated in BLUE and how the crankcase gases, GREEN, are drawn from each valve cover to be recirculated. The right hand valve cover breather (lower right) goes to a PCV valve while the upper left breather goes directly to the underside of the air cleaner cover. In addition the forced air passes through the Auxiliary Air Valve, as indicated on image to right. The AAV regulates your cold start idle and it in turn is regulated by engine coolant temperature. When the engine coolant is sufficiently warm the AAV will begin to close, bring the idle down. There is also an idle air bleed screw, which is a manual setting that regulates how high your idle will be during a cold start. More discussion on how to service the AAV in a subsequent article.

KEEPING YOUR AIR INJECTION IN LINE

Also indicated in the righthand image, is the cold start injector which supplies extra fuel when the engine is cold in order make the fuel air mixture more rich with fuel. The cold start injector is cut out when the engine is sufficiently warm. Finally in the line up is the fuel vapor purge valve. This purge valve is linked with the charcoal canister that receives the gasoline vapors from the fuel tank. Of the two lines exiting the valve, the first is routed to the lower portion of the throttle body. The second line is split between the vacuum control switch and the upper portion of the throttle body.

Air is also injected into cylinders (noted by the blue circles) by means of the air pump via a channel cut into the head, just below the intake manifold as shown. These holes were plugged with dirt and were reopened with a dental pick and a vacuum. Be advised, do not get dirt or debris inside the engine while you are working.

LOWERING ENGINE BAY TEMPERATURE

As mentioned earlier, the necessity to meet EPA regulations for emissions by the auto manufacturers didn’t leave sufficient time to fully test all of the idiosyncrasies that would rear their head in the hands of the customers. One such unforeseen event was the catalytic converter being mounted directly under the exhaust manifold. The proximity of the converters caused elevated heat levels in the engine bay, causing the fuel in the injection lines to boil causing vapor lock. It was quickly recognized by Mercedes-Benz that many who lived in hotter climates would face difficulty if not making it impossible to restart an already hot engine. In short, Mercedes relocated the catalytic converters down stream locating a duel-flow single unit in place of the resonator.

Since my 450SL lives in a very hot climate I have opted to change out the original configuration as shown in the photo (left) and have replaced with a set of 1973 450SEL manifolds. By making this switch, I will avoid any opportunity for the engine bay temperatures to rise high enough to cause vapor lock. The original manifolds & catalytic converters will be kept for the next owner.

To keep the car ready to pass inspection, a Magnaflow duel pipe catalytic converter will be fitted to the new exhaust system as shown.

This is obviously a very brief overview of how Mercedes dealt with meeting the demands of the EPA. Mercedes however did not use parts unique to them. The pump for example was a relatively common pump to many American cars of the day as was the one way check valve.

The good news, parts are readily available to keep our cars stock and able to pass emissions if need be. It is also good to know that renewing these parts is not a major undertaking but will take time. Cleaning all parts that will be reused is critical and making sure that all parts to be reused are in perfect shape. Even a small crack in any of the air lines will wreak havoc on your gas milage and over all engine performance.

You can check out the 450SL Catalytic Converter right here at FCP Euro.