Seems hard to believe it has been 45 years since the debut of the Mercedes-Benz “107” series

cars. These exceptional cars have endured the the test of time and timeless design, even by

today’s standards of styling and engineering. The Mercedes 107 production ran from 1972 to

1989, a masterful feat for a car that never saw a sheetmetal change.

While these cars were and still are highly sought after, they too suffer from idiosincrqocies that

demand attention. It is true, not all failing or non-working parts on our classics need immediate

attention, as some are more convenience based and do not compromise safety. That said

however, there are plenty of items that must be addressed and promptly!

The issue at hand, the Mercedes-Benz U.S.A. (MBUSA) front subframe TSB/Service Campaign

that was launched 11.1.1985, for select W and R107 series cars. It should be understood that at

no time was this issue classified as a recall, but a voluntary notification to owners of specified

107 models that were subject to a cracking front subframe. In short, only the 350 and 450 SL/

SLC models 107.023, 107.024, 107.043, 107.044 were covered by the agreement. From what I

understand, the European models and other models were never covered under this campaign.

But here we are, just around the corner from 2017, with a 40+ year old 450SL and discover the

car never went back to Mercedes in the mid-80’s for the inspection and repair or replacement of

the questionable subframe. Now what? Well, if you are the owner of an effected 107, and do not

know whether or not the subframe was replaced or repaired, simply call your local Mercedes-

Benz dealer, and provide the service department with your VIN. Within just a few minutes, you

will know what if any action is required.

WARNING: Make sure you know the status of your 107’s subframe. A subframe that fails while

driving, can have devastating results.

When I initially purchased my 1975 450SL this past summer, I did not do much research on

potential problems etc., as I was able to get the car for nearly free. Free however is not always a

good thing either, as it can still prove to be a money pit that will yield negative returns.

Regardless, I did have enough insight on this particular car to move forward, but did not know

anything of the campaign. Admittedly, I was quite shocked when I had the car inspected by our

local Mercedes dealer, to have my service advisor inform me of a 31 year old issue, from time of

notification, that had not been fulfilled. I immediately assumed the worst, but was quickly put at

ease when the service advisor assured me the campaign was still fully honored by Mercedes.

Impressive!

There are two “fixes” for the subframe that were agreed to by MBUSA and USDOT. The first, is

a four-piece bracing kit that is welded to the subframe. This kit would be installed if the

subframe had not already begun to fail. The second “fix”, is the replacement of the entire

subframe with a reengineered unit. You will only receive a new subframe should a crack or

cracks be discovered during inspection. I would personally be assured, Mercedes is not going to

take the easy way out on this one. I am also certain they do not want to have any legal

ramifications and I believe would quicker install a new subframe if in doubt. In either case, the

work is done at NO COST to the owner.

Should you be the recipient of a new subframe, NOW IS THE TIME to replace every single

rubber and normal wear component on the front end (excluding brakes etc.). You will save

yourself lot’s of money, and time having Mercedes do this work for you. This will be wrapped

into the “campaign” work. Be aware a few dollars out of pocket may be billed for fully removing

shocks and pressing old bushings in and out for example, but talk this over with your dealer.

The easiest and most cost effective way to go about this process is to purchase all your front

end items from FCP Euro and deliver them to your Mercedes-Benz dealer with the car. Know

that Mercedes will not warranty any of your personally purchased components, but remember

FCP does, so you are not at a disadvantage. NOTE: If you are only eligible for the bracing kit,

you would be billed for any front end components that you would have replaced as the bracing

kit installation does not require the disassembly of any front end parts.

Much to my surprise, I was notified that I would be receiving a new subframe, and so I

purchased the following replacement parts from FCP for the dealer to install. IMPORTANT:

Make sure you verify your chassis number for each component you purchase. The following list

is specific to a 1975 450SL with a 020000 (twenty thousand) series chassis. While many

components do cross over, chassis splits are common with Mercedes.

| PART NEEDED | QT. NEEDED |

|-----------------------------------------|------------|

| Mercedes Control Arm Bushing | 2 |

| Febi 1153301675F | |

| Mercedes Control Arm Repair Kit | 2 |

| Febi 1153301775 | |

| Mercedes Steering Drag Link Center | 1 |

| Meyle 1074600605 | |

| Mercedes Suspension Ball Joint Lower | 2 |

| Lemforder 1153331127 | |

| Mercedes Ball Joint Front Upper | 2 |

| Meyle 1153330827 | |

| Mercedes Steering Idler Arm Repair Kit | 1 |

| Febi 1264600819 | |

| Mercedes Shock Absorber Front | 2 |

| KYB KG4522 | |

| Mercedes Sway Bar Bushing Kit | 1 |

| Meyle 1153200047 | |

| Mercedes Steering Damper | 1 |

| Stabilus 0004635132 | |

| Mercedes Steering Tie Rod Assembly | 2 |

| Febi 1073300103 (Left & Right) | |

| Mercedes Suspension Subframe Mount | 1 |

| Febi 1153301875 | |

| Mercedes Engine Mount 450SL/SLC | 1 |

| Meyle 1072412313 (Right Side) | |

| Mercedes Engine Mount 450SL/SLC | 1 |

| Meyle 1072412413 (Left Side) | |

FCP also carries various brands on many of the components listed above. I happened to

choose components that I believe deliver good value based on the particular manufacturer.

With components in hand and packed in the trunk, the 450SL is off to Mercedes for a new front

end! The process took 3 days.

The following photos show the process in brief detail. Unfortunately I was not able to hang out in

the shop due to insurance reasons but could grab a few photos prior to the work commencing.

My service advisor was gracious enough to provide me with the last 2 photos.

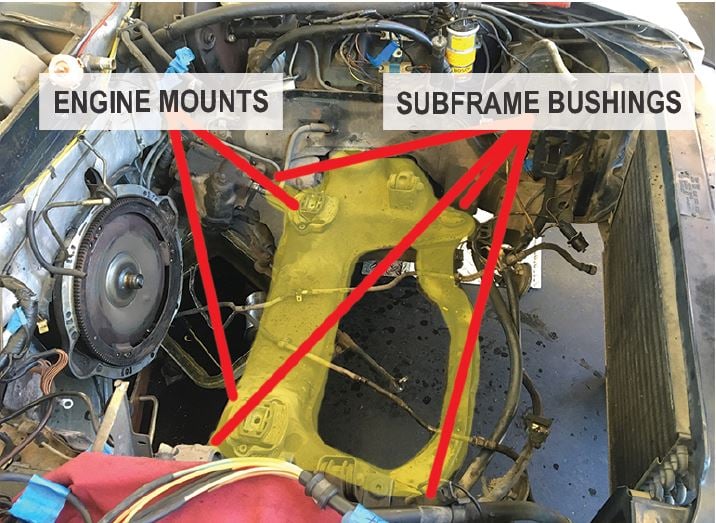

Subframe prior to removal highlighted in yellow—view 1

Subframe highlighted in yellow—view 2. Shown, 1975 450SL engine bay

Proper brace to support engine when subframe is removed on 450SL

New 107 subframe from Mercedes-Benz. Red boxes indicate redesign (reinforced) section to

prevent future cracking issues.

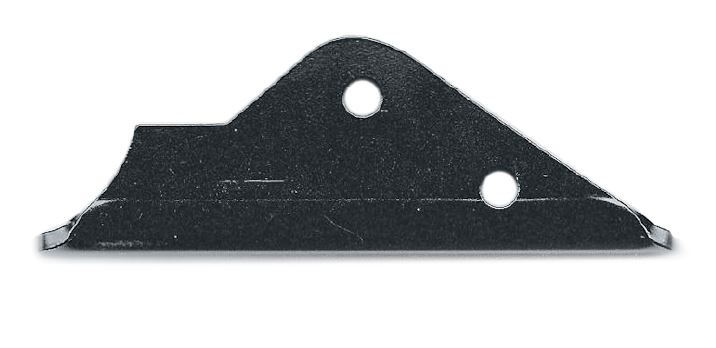

If the subframe is not cracked, a bracing kit is welded in. The image above shows one of the 4

brace tabs Mercedes provides for the job.

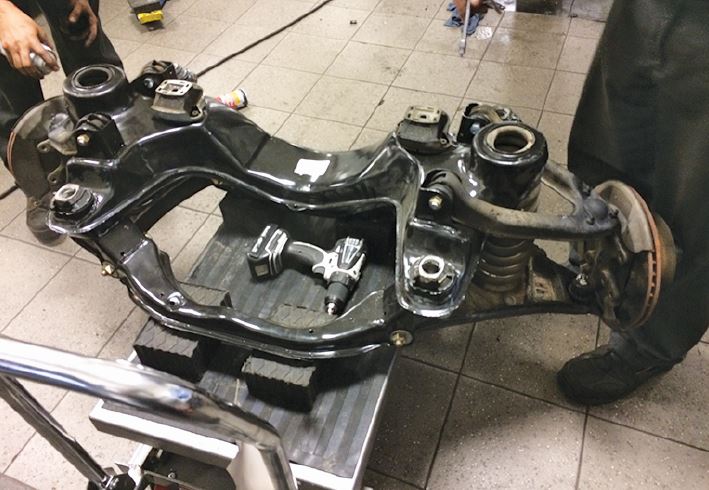

Subframe assembly and components removed

New subframe fitted with original components, i.e., springs, control arms, brakes, etc. and ready

for installation.