- 10/07/2020

- 9 Min Read

- By: Christian Schaefer

How To Overhaul The BMW E46 M3 Rear Subframe (Part 2)

This is part two of three of the BMW E46 M3 rear subframe overhaul DIY. Part one of the DIY covered the entire removal/teardown process, setting up part two for the next steps of replacing the various suspension components. Part three covers the re-installation process once the bushings and mounts are replaced.

BMW E46 M3 Rear Subframe Overhaul Part 1

BMW models and years applicable:

- 2001-2006 BMW M3

- 2006-2008 BMW Z4M

Why should you overhaul your BMW E46 M3 rear subframe?

Since the chassis' debut in 2000, the rear subframe issues have been a constant source of worry from owners. The subframe mounting points in the chassis are prone to cracking and have failed in some cases. BMW and aftermarket companies have all come out with weld-in reinforcement plating to help prevent this issue.

Along with the subframe mounting points, the rear trailing arm bushing mounts are prone to the same kind of cracking and failure. Reinforcement plating for these mounting areas will come with the subframe reinforcement kits.

Beyond the cracking issues, worn bushings and mounts will create problems of their own. The OEM rear trailing arm bushings are rubber and degrade quickly from use. As they get softer, the back end becomes more unpredictable under braking and through the corners. Aftermarket companies produce polyurethane bushings and press-in Heim joints to replace the OEM softness. The differential mount bushings can also be changed to aftermarket polyurethane to remove the sloppy acceleration feeling that worn OEM rubber mounts will give you.

How long will it take to overhaul a BMW E46 M3 rear subframe?

This DIY is not for the faint of heart, and its complexity is reflected in the time required to complete the job. Even with all of the proper tools, lots of space, and help, this job can take several days. The youngest chassis is now 16 years old, and corrosion is relatively standard. Fighting with seized or stripped bolts is a real possibility and a time killer.

If you can, gain access to a lift. Having a shop with air tools and a press can speed the process up, but won't guarantee anything. A good torch will help with removing any corroded fasteners. Put aside at least a full weekend if you intend to take on this project in your garage or driveway.

What will it cost to overhaul a BMW E46 M3 rear subframe?

Beyond fixing any possible cracks in the chassis, the bushings in the subframe should be replaced. Factory bushings are fine, but there are several upgraded choices that we recommend. In this DIY, we use Synchro Design's rear trailing arm bushings. Their monoball kit eliminates the twitchy back end that develops when the factory bushings start to wear. Their bushings cost $265.

The differential mounts that we install in the DIY come from Revshift. They are made from polyurethane and are a slightly higher durometer than the factory rubber pieces. The kit costs $109. Additionally, we install Eibach rear camber arms. These eliminate the need for the eccentric bolt that BMW uses for the camber adjustment in the rear of the car. The new arms are adjustable, making up for the lack of eccentric bolt. The Eibach arms cost roughly $200.

In total, the upgraded parts cost roughly $580.

Parts required to overhaul a BMW E46 M3 rear subframe:

Tools required to overhaul a BMW E46 M3 rear subframe:

- Floor Jacks

- Jack Stands

- Pry Bars

- 24oz mallet

- 32oz ball peen hammer

- 24oz ball peen hammer

- Metal file

- Brass punch

- 1/2" torque wrench

- Ratchets

- Ratchet Extensions

- Large & small channel lock pliers

- Pliers

- Side cutters

- Needle nose pliers

- Various picks

- Screwdrivers

- 16mm stubby ratcheting wrench

- 13mm stubby ratcheting wrench

- 12mm stubby ratcheting wrench

- 17mm stubby ratcheting wrench

- 19mm stubby ratcheting wrench

- 12mm box end ratcheting wrench

- 11mm box end ratcheting wrench

- 10mm box end ratcheting wrench

- 13mm box end ratcheting wrench

- 16mm box end ratcheting wrench

- 18mm box end ratcheting wrench

- 19mm box end ratcheting wrench

- 21mm box end ratcheting wrench

- 14mm wrench

- 16mm wrench

- 17mm wrench

- 18mm wrench

- 19mm wrench

- 24mm wrench

- 27mm wrench

- E12 socket

- E14 socket

- E16 socket

- 8mm socket

- 10mm socket

- 13mm socket

- 16mm socket

- 17mm socket

- 19mm socket

- 22mm socket

- 6mm six-point

- 7mm six-point

- 8mm impact socket

- 9mm impact socket

- 12mm impact socket

- 13mm impact socket

- 16mm impact socket

- 17mm impact socket

- 18mm impact socket

- 19mm impact socket

- 21mm impact socket

- 22mm impact socket

- 30mm impact socket

Steps required to overhaul a BMW E46 M3 rear subframe:

Step 1: Separate the differential from the subframe

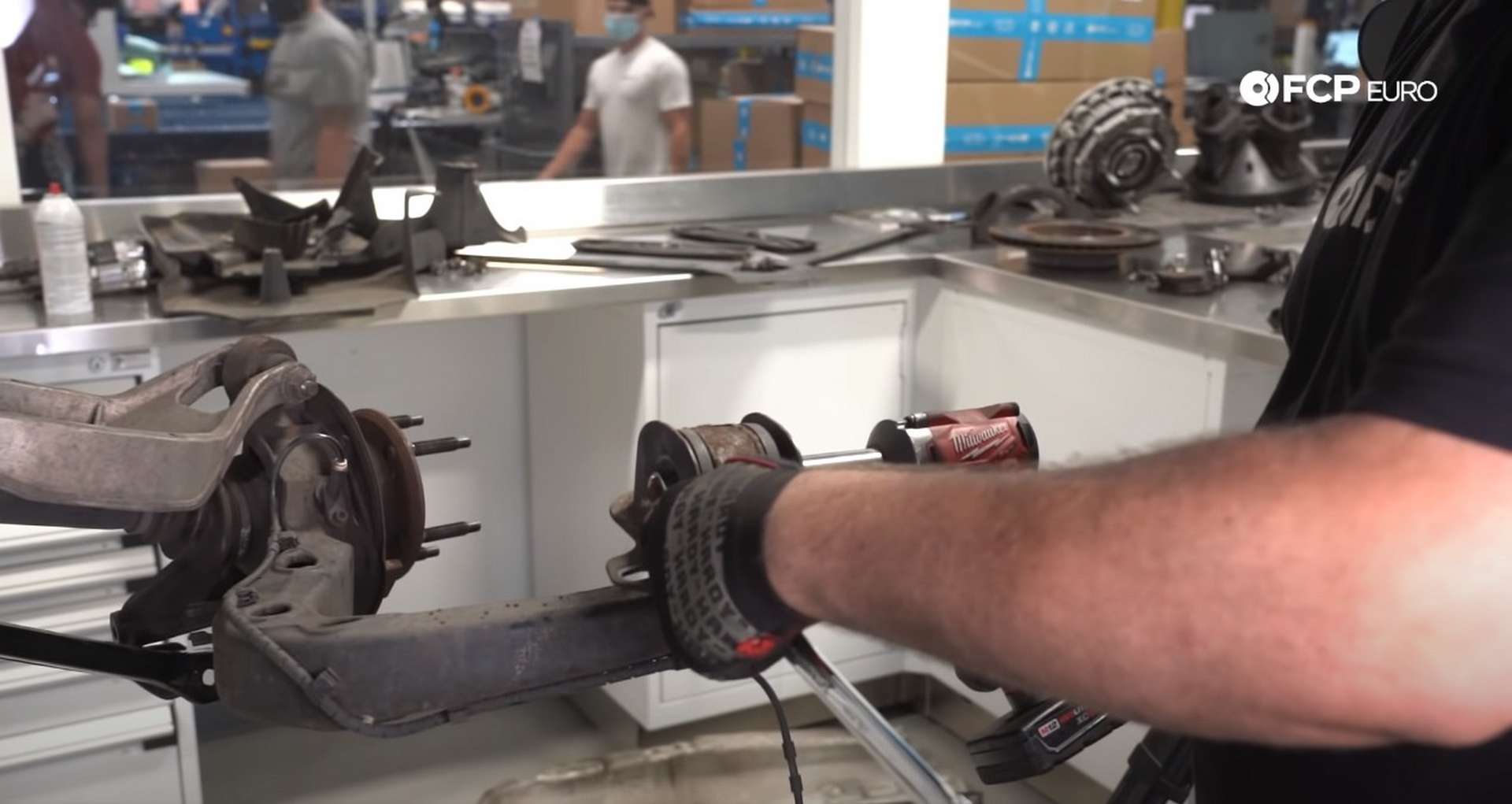

Using an 18mm socket for the nut and an 18mm wrench to counter-hold the bolt head, remove the trailing arm bracket from the trailing arm.

Next, unbolt the sway bar from the subframe. Use a 13mm socket to remove the four bolts mounting the sway bar bushings to the subframe. Then, use a 17mm socket to remove the endlink brackets from the upper control arm.

Pull the swaybar down and out of the rear subframe assembly. Next, use an E12 socket and remove the eight axle bolts per side.

Then, use an E14 socket to remove the two differential mounting bolts. At the front of the diff, next to the driveshaft flange, is the last mounting bolt. Use an E21 socket to remove it.

Now, however, you can remove the differential from the subframe. If you have a partner, try lifting the subframe assembly off of the differential. If you are alone, try sliding the subframe assembly forward; this should leave the differential behind.

Step 2: Strip the subframe

Using an 18mm wrench and socket, remove the lone bolt holding the knuckle assembly to the upper control arm on each side.

Then, flip the subframe over and use an 18mm socket to remove the two bolts that hold in each of the camber arms.

Next to one of the camber arm mounting points is the headlight level sensor bracket. Use a 10mm socket or wrench to remove the bolts and the sensor.

Lastly, use an 18mm wrench and socket to remove the two bolts that secure the upper control arms to the subframe.

Step 3: Replace the bushings

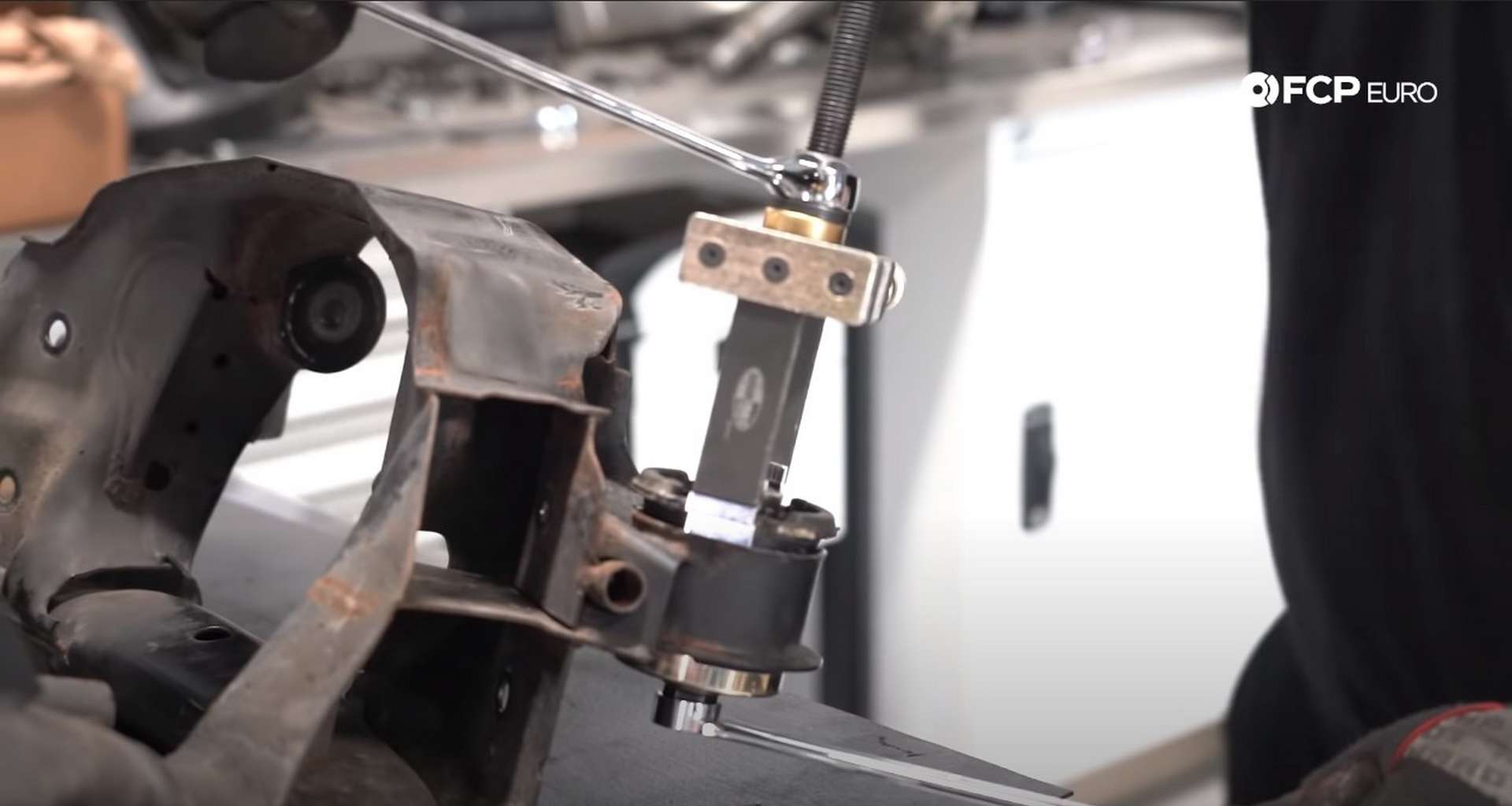

Use the BMW bushing removal tool to remove the subframe bushings. Use a 24mm wrench for the top nut and a 19mm wrench to counter-hold the bottom. As you tighten the top nut, the tool will pull the bushing up and out of the subframe. Without the tool, using a press or burning the bushing out are the next options. The latter option, however, is not recommended.

Then, use the differential bushing removal tool to press out the two bushings in the differential cover and the one differential bushing in the subframe.

The new subframe and differential bushings are a two-piece design. Push each piece by hand into place and then use a dead-blow mallet to make sure they are seated. The forward differential mounts have a small machined area, specific to the front subframe mount holes. The rear mounts are strictly round. Don’t forget to use the small packet of lubricant included with the subframe bushings.

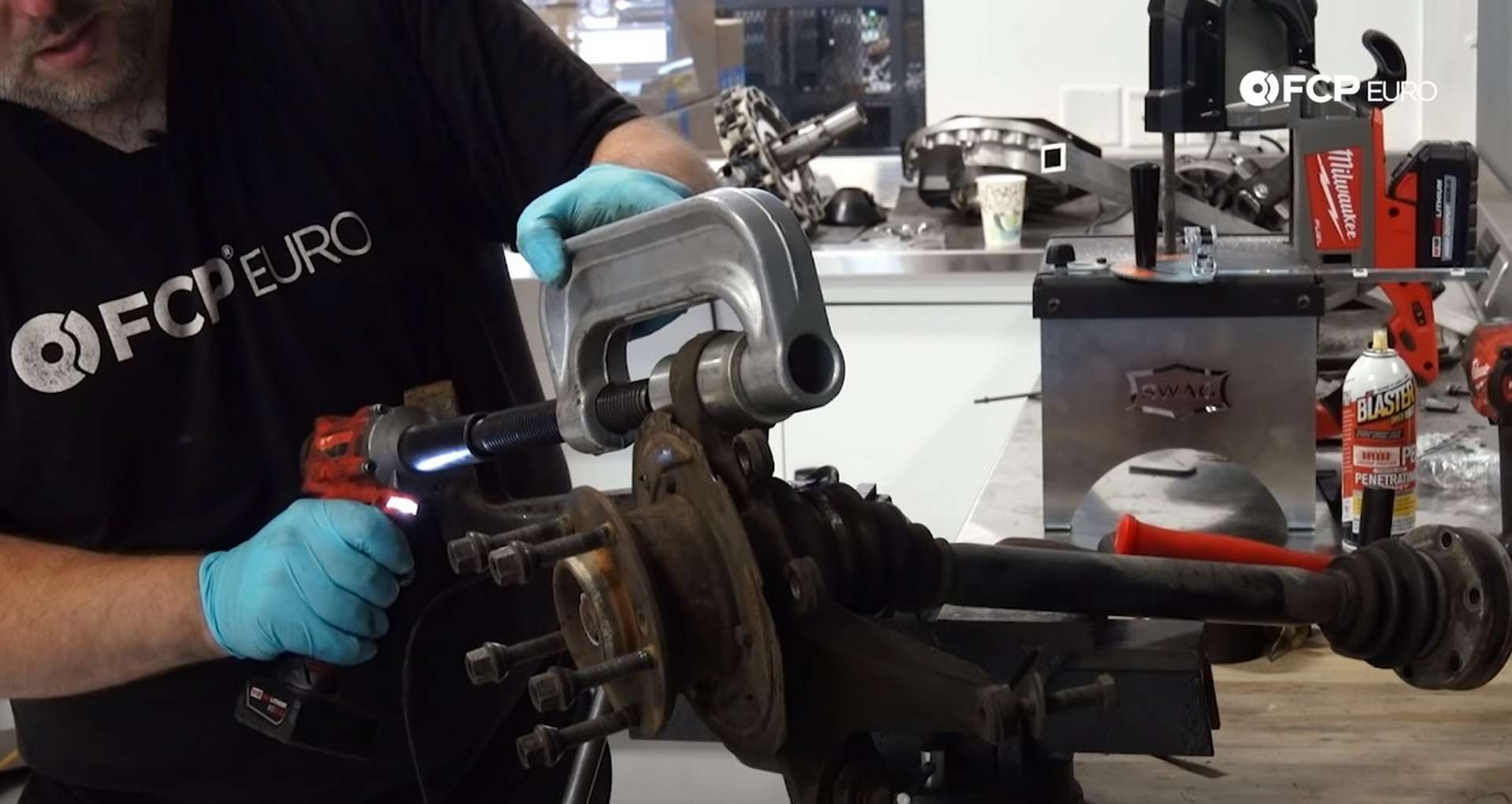

With all of the bushings replaced on the subframe, move onto the knuckles and trailing arms. If you bought new bushings, use the removal tool on the upper control arm bushing in the knuckle. The same tool used for the removal can be used to press them in. Press the upper and lower control arm bushings into the knuckle until an even amount of bushing sleeve is visible on both sides.

Last but not least, the rear trailing arm bushings need to be installed. After removing the old bushings, take a wire wheel or sandpaper and clean up the inside of the trailing arm bushing sleeve. The aim is to remove any rust that may be present. Then, use what you can to press the Synchro Design RTABs into place. Finally, reinstall the trailing arm brackets. Use an 18mm wrench and socket to torque the bolts to 110Nm.

The hard part is now complete, and everything can be reassembled. Keep an eye out for Part 3 of this DIY, where we show you how to install your freshly improved subframe and rear suspension assembly back into the car. If you're interested in more DIYs for your BMW, you can visit bmw.fcpeuro.com and subscribe to our YouTube channel.

If you have any questions about this process, leave them in our comments section below.