Mercedes vehicles have combined large displacement and big power with a plush ride and cozy interior for over half a century. Both long-term and short-term owners of Silver Arrows know that due to this trademark smoothness, few parts of ownership are more irritating than an intermittent but prominent chassis vibration present at idle and at low speeds. It’s widespread across Mercedes products, and owners often spend far more than necessary to regain their occupancy comfort. Fortunately, you can follow this simple checklist to properly diagnose your Mercedes idle vibration on the first try to fix it as quickly and cheaply as possible.

Step 1: Grab a Scanner

When an intermittent or constant vibration is present, owners often jump to a tune-up, grabbing ignition coils, wires, and spark plugs, however applicable to their engine. While not always the case, a failure from one of those parts can cause an idle vibration. On the late 1990s and early 2000s engines, like the M112, M113, and M137 that use a twin-spark system, a plug can start going bad or stop firing entirely with near-zero repercussions toward driveability. Engines with a more traditional single-plug-per-cylinder ignition system may also disguise a light misfire, but it should be more noticeable.

For this reason, an excellent first course of action in resolving a vibration is to plug in a suitable OBDII diagnostic device (where OBDII is applicable) and look for any signs of a misfire condition. These can be obvious in the form of a check engine light for a specific cylinder or may require live data to monitor individual cylinders for particular instances of misfire. Regardless, if the bill of health comes back clean, the ignition system is probably not the vibration you’re experiencing.

Step 2: Pop the Hood

Most Mercedes vehicles sporting multiple-cylinder banks use engine air filters integrated into the engine beauty cover. Acting both functionally (to channel inlet air properly) as well as cosmetically (providing a polished touch to the engine bay), these hard black plastic covers include an air inlet from the front of the vehicle, a housing for the engine air filters, and an outlet that seals onto the mass airflow sensor.

The air filter housing seals to the mass airflow sensor via a large rubber o-ring, but extended use can cause it to tear or shrink slightly, causing a vacuum leak. As the engine pulls in a tiny bit of air from the potential tear or poorly seated filter housing, the engine won’t be able to compensate for it and develop a rough idle. This is one of the most common causes for an idle vibration and often will come hand-in-hand with a perceived loss of power driving around town at low speeds. You’ll feel like the car suddenly requires more throttle input to drive normally.

Checking for this is pretty simple. Reaching your fingers back to the mass airflow sensor and feeling to be sure that the rubber seal is mounted flush will generally be sufficient in deciphering whether the air filter housing is appropriately installed, whereas checking the wear and condition of the seal will require you to pull the engine cover off and inspect it visually. While it is also a possibility that the mass airflow sensor is failing or bad, that would typically be detected during your code scan in step one.

Step 3: Check your Mounts

To ensure the earth-moving torque doesn’t disrupt passengers, Mercedes utilizes soft hydraulic rubber engine mounts and transmission mounts to absorb as much energy and vibration as possible. While this practice is generally very effective at keeping the cabin isolated from noise and vibration, the crux of these mounts is generally their accelerated wear and failure rate versus other vehicles in the segment.

The pliability of the stock Mercedes and AMG mounts combined with the axle-twisting torque of high-output powertrains generally leads to the eventual tearing of the soft hydraulic rubber mounting points. Replacement, while dependent on driving style, drivetrain, and vehicle, can be warranted as frequently as every 30,000-50,000 miles.

In a traditional rear-drive format, Mercedes vehicles will use three “engine” mounts: one hydraulic mount on either side of the engine and a third rubber mount underneath the transmission (this is the transmission mount, but it’s also responsible for a good deal of rearward engine motion). When the engine mounts begin to fail, they collapse and allow for metal-to-metal contact with the chassis - a common cause for idle vibration felt in the cabin. This behavior can become present relatively early in the failure of the engine mount and will only worsen when left in place.

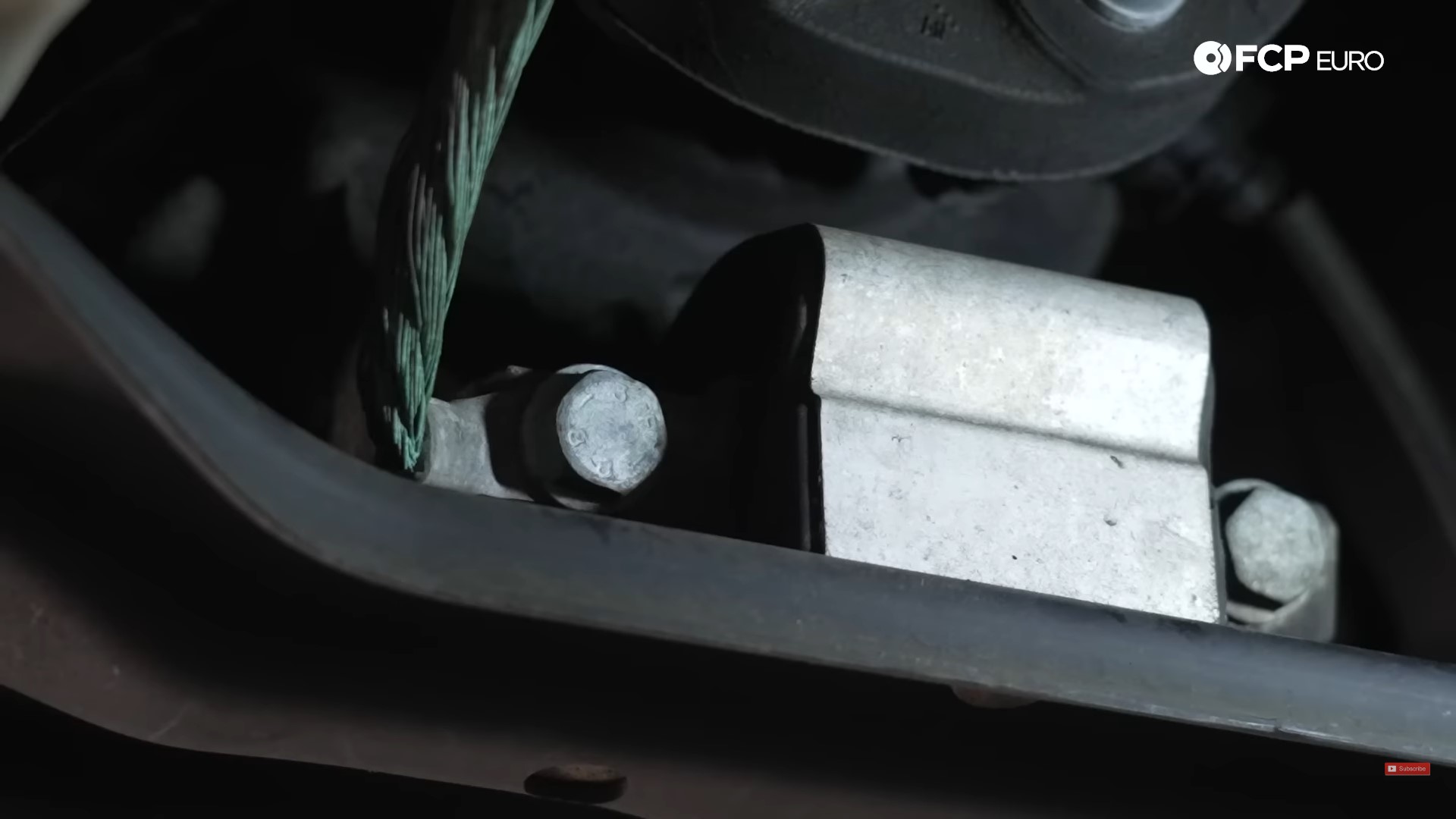

Identifying the failure of a transmission mount is as simple as a visual inspection of the mount underneath. If there are any signs of damaged rubber or leaking fluids, it’s time for a replacement. You’ll want to replace it as soon as you can, too, considering it’ll accelerate the wear of the other mounts and allow for that metal-to-metal contact, resulting in unwanted vibration.

A failed engine mount is generally even simpler to distinguish; pop the hood, start the vehicle, place it in neutral, and rev the engine gently once it reaches operating temperature. If the engine hardly moves, try taking your foot off the gas and alternating between neutral, drive, and reverse. That’ll adequately place a load on the drivetrain and may make any visual excess engine movement more pronounced.

If it still isn’t clear whether or not the engine mount has failed after the test above, the next step is getting underneath the vehicle to remove the belly pan for a visual inspection. As they’re hydraulic, a trademark sign of failure will be any residue or leakage of brown fluid from these mounts. A fully collapsed mount will also appear to be squished underneath the metal engine mount bracket affixed to the side of the engine block.

Step 4: Transmission Internals

While the steps above will generally be successful in resolving an idle vibration, you may reach the end of this list with no clear course of action or cause for the issue. A smart subsequent step would be to reflect on when the car last received a transmission service. Mercedes marketed a host of their transmissions, from the 722.6 to the 722.9 and beyond, as “lifetime-filled.” In reality, these transmissions will warrant a fluid and filter change at regular intervals to continue operating smoothly and seamlessly.

Old fluid can induce odd transmission behavior, ranging from harsh or flared shifts to the same engine vibration we’ve been discussing. Similarly, a failing transmission solenoid (often the Torque Converter Lockup Solenoid in the case of the 722.6) can cause an irritating and intermittent idle vibration. If none of the above issues are clearly present, try using the OBDII or appropriate scanner on the transmission. If no fault codes arise, service the transmission with a fresh filter and fluid (and while doing so, inspect the transmission pan for any extreme signs of metallic wear indicating a larger concern).

Step 5: Exceptions

Historically, Mercedes 4MATIC-equipped vehicles demonstrated an issue with tolerances on aftermarket front axles. Those who replaced their front drive axles with non-genuine products would find that even when stationary, an incessant idle vibration would persist following ignition servicing, engine mounts, and all of the above-recommended practices. Swapping to Genuine Mercedes front axles in these cases will typically eliminate the vibration. If all else has failed to yield a smoking gun and your Mercedes is 4MATIC, check to see if your front axles are an aftermarket replacement.