- 08/05/2014

- 2 Min Read

- By: Dan Bullmore

Bosch K-Jetronic Engine Management in a '90 300E Mercedes

When I was a kid we had a Volvo 265, with the infamous PRV V-6 engine and K-Jetronic injection. My dad often made the joke that the K was German for Komplicated, but after having many K-Jetronic equipped cars in the family, I have come to love the system.

The dawn of fuel injection

The dawn of fuel injection

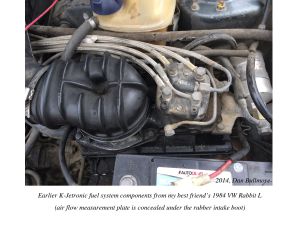

Many of us with older fuel injected European autos either own a car with K Jetronic, or have worked with one in the past. K Jetronic (also commonly known as CIS or Continuous Injection System) is an early mechanical fuel injection system developed by Bosch and used by pretty much every major European manufacturer at some time or another. These systems are especially common in Mercedes, where they were used for years in models from the 70's to the 90's, and in Volvos where they were used from the 70's and into the early 80's. K Jetronic was phased out in favor of LH Jetronic, which came about in the mid 1980s and was an electronically controlled system.

Despite the fact that the system sounds very simple in theory, it is an extremely delicate system that must be tuned well to provide factory intended performance.

K Jetronic has a few strange characteristics that make it unique

1. The injectors are constantly spraying, and never truly close until the fuel pump shuts off.

2. The entire fuel system is kept under (relative) high pressure, from the pump, all the way to the injectors. In the case of my 1990 Mercedes 300E, the pressure is about 70 PSI.

3. The system can run without any electric power, making it very convenient for the rare episode where your Bosch alternator gives out, (I'll be covering that issue shortly, as well)

Fuel delivery

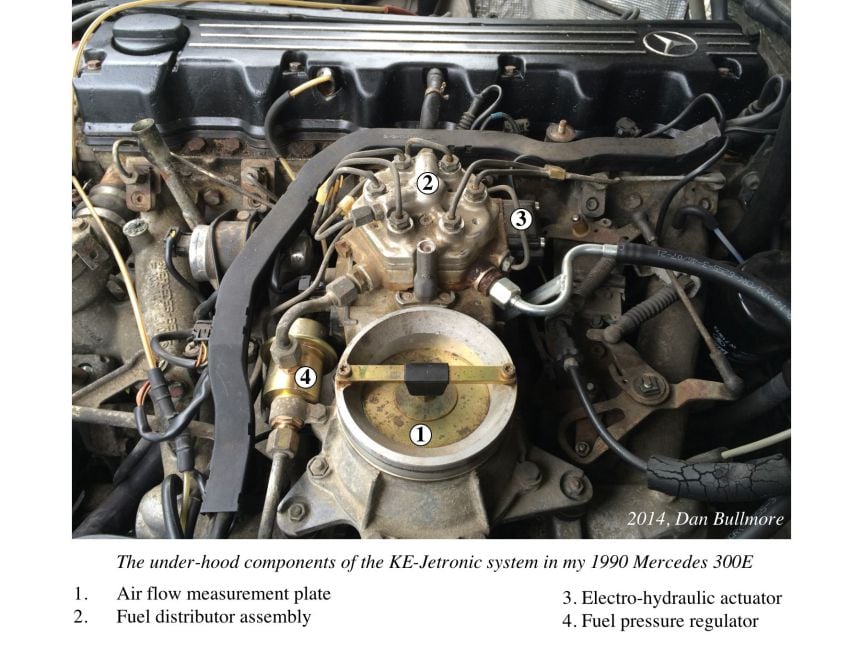

The K Jetronic system consists of a pump (or two) near the tank which brings the fuel line pressure up high enough to open the mechanical fuel injectors at the intake manifold. The fuel line pressure is maintained by a pressure regulator near the distribution block, and a pressure accumulator near the pumps. This ensures easy starting when warm, and less cranking when cold. The pressure inside the K-Jet' apparatus is modulated by a piston that either releases more fuel to the injectors at higher throttle, or less at lower throttle. This piston is driven by a lever, while the far side of the lever is attached to a plate that covers the intake duct. As the throttle opens and more and more air is sucked through the intake, the plate is deflected into the intake duct, which in turn pushes the control piston up in it's housing. This piston controls the flow rate to the injectors with the correctly metered amount of fuel via the distribution block on top of the K-Jet' apparatus.

Leaks aren't uncommon

The pressure differential between the upper and lower chambers ofthe K-Jet' apparatus is of critical importance to properly metering the fuel. To this end, the system incorporates a set of spring backed diaphragms between the upper and lower chambers to ensure that the pressure differential stays constant under any fuel flow situation. Later KE Jetronic systems with electronic control also employ what is known as the EHA or Electro Hydraulic Actuator, which can adjust the lower chamber pressure as a means of fine tuning the fuel delivery rate to the injectors. This actuator is adjustable, but this adjustment is usually not advisable without proper factory equipment. Especially in Mercedes, the actuator is considered a “frequent offender” when drivability is concerned because they are known to leak at their seals. A smell of gasoline, or a particularly clean looking appearance around the EHA is often a sign of a leak, and replacement or re-sealing is often the solution.

Later KE Jetronic systems use input from an oxygen (or Lambda) sensor to perfect the balance between upper and lower chamber pressures by influencing the function of the EHA through the computer. In this way, the car can continuously monitor it's emissions and adjust itself to accomodate changes in performance.

As with any other system not designed by the car's manufacturer, the K Jetronic system varies to some degree for each manufacturer that used it. The principle is generally the same, though there may be differences in sensors to adjust for temperature or atmospheric effects, as well as other considerations.

A new set of injectors is money well spent

Because a K Jetronic system uses fully mechanical fuel injectors, they are often difficult to diagnose without removal and bench testing. I will, however, say from experience, that no single repair I've ever made to my K Jetronic automobile has been as drastic as replacing the fuel injectors. Overtime, they may begin to bleed down which can cause vaporlock when the car is warm, or require extended cranking to build pressure when cold. Poorly functioning injectors can also cause hesitation on acceleration, difficulty at low RPM but normal drivability at high RPM, as well as damage to plugs and exhaust treatment equipment. A new set of injectors is typically money well spent, especially since they are relatively inexpensive and are not typically a maintenance item.

In short, the K Jetronic system is simple in function, complex in design, beautiful in engineering, and a pleasure to work with if you have the patience to learn it's intricacies.

Shop Mercedes-Benz at FCP Euro

Dan Bullmore is a physicist and engineer from Houston, TX. Preferring the old to the new, Dan has owned many examples of Mercedes and Volvos and has devoted much of his time to maintaining and understanding them.

Dan Bullmore is a physicist and engineer from Houston, TX. Preferring the old to the new, Dan has owned many examples of Mercedes and Volvos and has devoted much of his time to maintaining and understanding them.