The problem: The fan on the BMW 540i is only indirectly connected to the motor, and the viscous coupling is a separate unit in the middle of the fan. The fan is plastic and fan failures have been known to pierce the hood.

Symptoms: “Whooshing” noise from engine that is engine rpm dependent.

Verification: There are some suggestions out there to stick paper in the fan to test the viscous coupling strength. Sounds risky. With the motor off, turn the fan by hand. Grinding in the bearing? Very stiff, as opposed to smooth and rotates a partial rotation after spinning by hand? Bad fan clutch.

Tools: 1.25” (or 32 mm) open end wrench, rubber mallet and “Special” (homemade) pulley grabber tool-thingy. Tool construction details below.

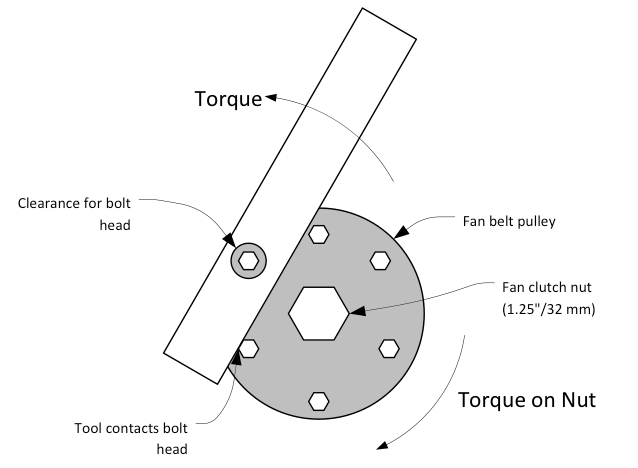

To remove the fan you need to unscrew it, clock-wise from the motor. The problem is that you can’t generate enough torque on the nut to loosen it before the pulley slips with only the belt holding from slipping. You need a metal plate that has a hole drilled in it that will clear the bolt head on the pulley and allow the plate to get wedged up against the shaft. Then you can use either a 1.25 inch or 32 mm open end wrench to undo the fan/fan clutch assembly.

Note: be careful unscrewing the fan, as the assembly is on the heavy side, the plastic is probably getting brittle with age and if you drop it, you’ll more than likely going to be sorry. I plan to replace the fan and clutch at once.

Here’s the idea:

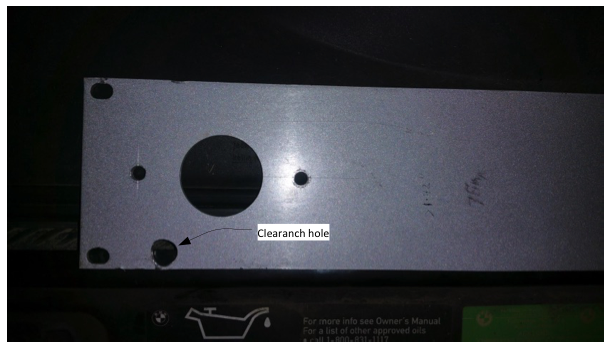

Here’s a picture of the “special tool”. It’s a 1/8” Aluminum front panel from an old electronic instrument. Ignore all the holes but the labelled one. Note how well I managed to drill that clearance hole. It needs to be close enough to the edge to clear the fan nut, but not so close to the edge that it breaks in use. I assume metal supermarket, or home depot Aluminum sheet would also work.

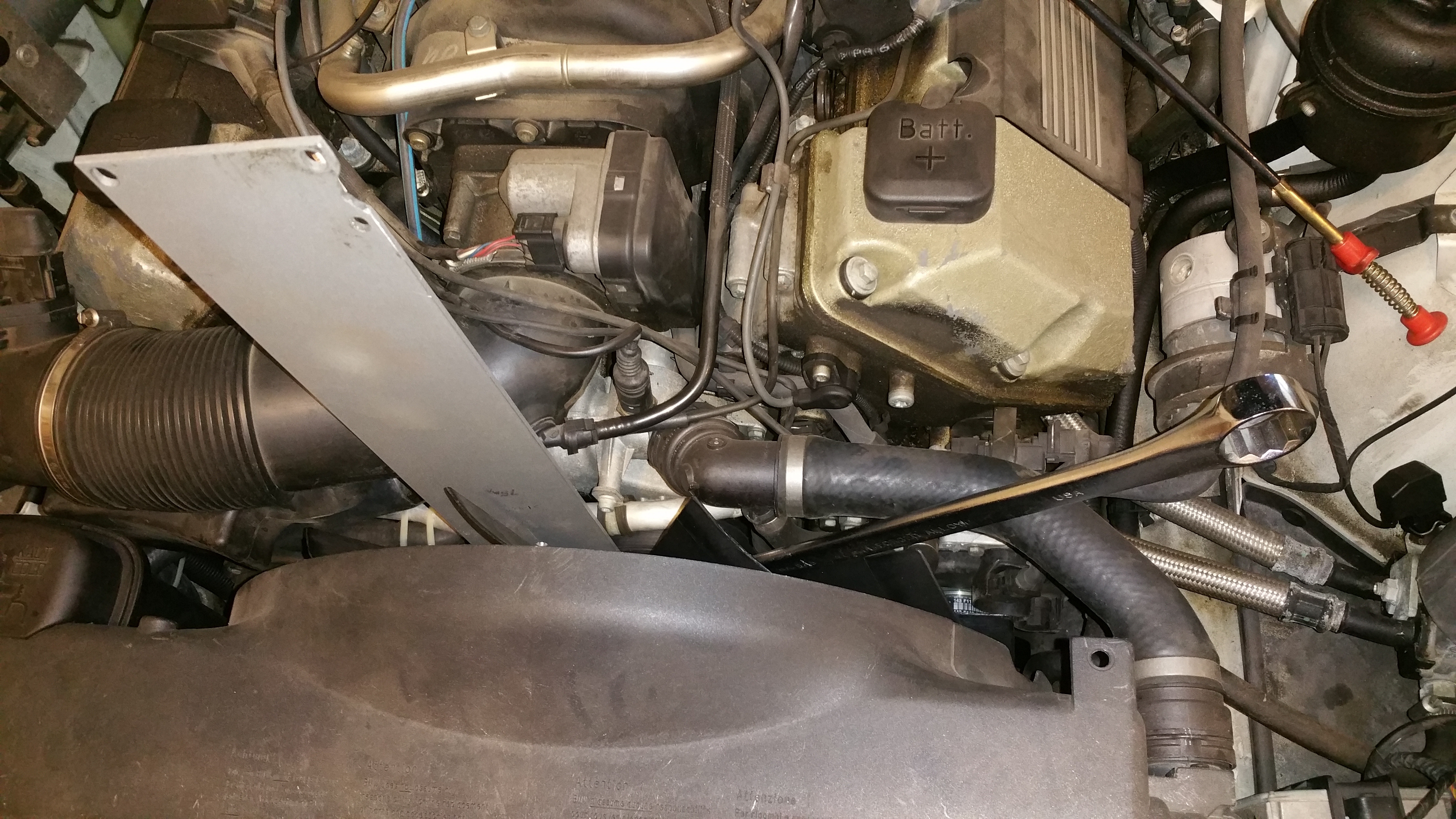

Here’s the tool and wrench in place. With the tool on first, the wrench actually holds it in place.

Another view, from directly above. Note how the wrench is holding the “special tool” in place, there’s no slop at all. Hold the “special tool” and hit the wrench with the mallet.

With the assembly removed, the 3 Allen head bolts holding the viscous clutch to the plastic fan can be removed. This picture shows just how well a 1.25” wrench fits the “supposed” 32 mm metric nut.