- 10/21/2021

- 8 Min Read

- By: Christian Schaefer

The Definitive Guide To The ZF 8-Speed Transmission (8HP45) - Specs, Common Problems, Diagnostics, & Maintenance

ZF Friedrichshafen was formed just after the turn of the 20th century in Germany. Initially, ZF was dedicated to designing parts for Zeppelins, but the quickly growing automobile industry soon became their main focus. By 1934, Zahnradfabrik Friedrichshafen had built their first fully synchronized manual gearbox, complete with “silent” helical gears. Fast forward to the 1960s and ZF’s development of an automatic transmission for European vehicles was underway. The European market was largely ignorant of the automatic transmissions so popular in the US, and many of ZF’s colleagues believed their development wasn’t worth the effort. ZF’s first automatic was the 2HP14 from 1958, but it was unsuitable for city driving. After more development, the 3HP12 debuted in 1961 and entered into testing with BMW and Peugeot. By 1965, the 3HP was rolling off the production line in volume, destined for BMW and Peugeot showroom floors.

Since the 3HP found its way into production models, ZF has become synonymous with automatic transmissions. From their humble beginnings in Friedrichshafen, ZF has become a global leader in transmission design and manufacturing. Today, their 8-speed 8HP transmissions are in use by over 20 manufacturers across the globe as the premier automatic transmission of this generation of vehicles. So what makes up the current gold standard? Find out below.

ZF 8HP Transmission Guide Sections |

ZF 8-Speed Specifications

8HP45 Gear Ratios:

- 1st gear 4.71

- 2nd gear 3.14

- 3rd gear 2.11

- 4th gear 1.67

- 5th gear 1.29

- 6th gear 1.00

- 7th gear 0.84

- 8th gear 0.67

- Reverse 3.30

- Fluid Capacity: Roughly 6 liters

- Fluid Type: ZF LifeguardFluid 8 or equivalent

- Torque Limit: 450 NM (332 lb-ft)

8HP50 (Gen 2) Gear Ratios:

- 1st gear 5.00

- 2nd gear 3.20

- 3rd gear 2.14

- 4th gear 1.72

- 5th gear 1.31

- 6th gear 1.00

- 7th gear 0.82

- 8th gear 0.64

- Reverse 3.46

- Fluid Capacity: Roughly 6 liters

- Fluid Type: ZF LifeguardFluid 8 or equivalent

- Torque Limit: 500 NM (369 lb-ft)

8HP51 (Gen 3) Gear Ratios:

- 1st gear 5.25

- 2nd gear 3.36

- 3rd gear 2.17

- 4th gear 1.72

- 5th gear 1.32

- 6th gear 1.00

- 7th gear 0.82

- 8th gear 0.64

- Reverse 3.71

- Fluid Capacity: Roughly 6 liters

- Fluid Type: ZF LifeguardFluid 8 or equivalent

- Torque Limit: 500 NM (369 lb-ft)

ZF 8-Speed Component Overview

When the 8HP45 debuted in 2009, it immediately became the class of the field. The new gearbox was explicitly built with efficiency and emissions in mind. The writing was on the wall for internal combustion engines with increasingly strict emissions standards, so the 8HP was to be the benchmark.

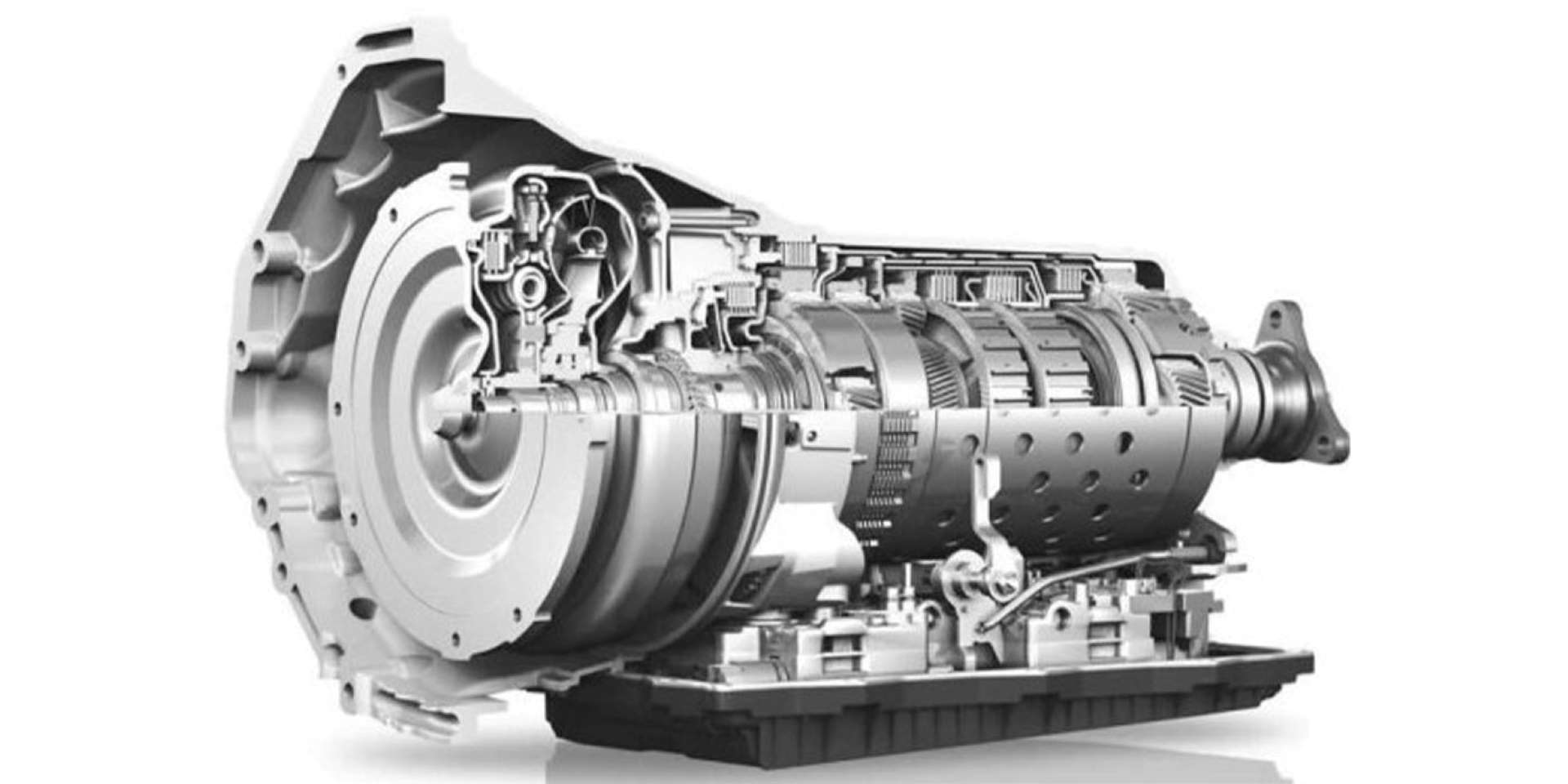

Gear Sets

The 8-speed gearboxes used four planetary gear sets, five shift elements, two brakes, and three clutch packs. While that sounds like a lot, it’s relatively simple for a modern eight-speed automatic. The compact design helped ZF keep the gearbox the same size as its predecessor, the six-speed 6HP, while reducing its overall weight by three percent. The lack of internal components also helps with efficiency; the fewer components, the less energy is wasted spinning them. Only three of the five shift elements are used in any gear, reducing the drag on the rotating assembly. ZF’s choice of ratios was also in its pursuit to deliver efficiency. The first generation of 8HP45 achieved a spread of 7.05, burying its predecessors 6.05. The wider the spread, the longer the ratios, which in turn keeps the RPMs down when cruising.

Torque Converter

At the front of the transmission sits the torque converter, the device used in place of a clutch that smoothly transfers the engine's torque to the transmission. ZF knew it couldn’t stop at just a transmission redesign, so they also re-engineered the torque converter. For the 8HP, the torque converter featured adaptable lock-up clutches and the Twin-Torsional Damper. The torque converter is modular, with room for 2, 4, or 6 clutches, depending on the application’s needs.

The TTD system reduces unwanted vibrations and works together with the clutches. Together, those features let the transmission select the next gear earlier without sacrificing fuel economy. Their ability to select a gear earlier is made possible by the ever-increasing torque offered by modern engines while allowing the ratio spread to be increased further to improve fuel consumption.

Transmission Control Unit (TCU)

Controlling the transmission is the integrated transmission control unit. The TCU works directly with ZF’s electronic valve body, also known as the Mechatronics. The valve body is the mechanical piece responsible for actuating shift changes and shift points. When combined with the integrated TCU, the electronic valve body could actuate the quickest shifts this side of a dual-clutch while reducing internal hydraulic drag during coasting for a significant bump in efficiency and economy.

Hydraulic Impulse Oil System (HIS)

ZF understood while designing the 8-speed that different manufacturers had different requirements. To appeal to as many manufacturers as possible, ZF made the 8HP modular, allowing for different options to be installed without a major fuss. For vehicles with a stop/start function, ZF created their hydraulic impulse oil storage system, or HIS. Traditional stop/start functions used an auxiliary pump to pressurize the small amount of oil needed to resume drive function quickly. However, a HIS-equipped 8-speed does not need an external pump; all the components required to supply that 100 centiliters of fluid are within the transmission. In testing, ZF found that the 8HP reduces fuel consumption by 6% over its predecessor. With the HIS equipped, that vehicle sees another 5% reduction in fuel consumption.

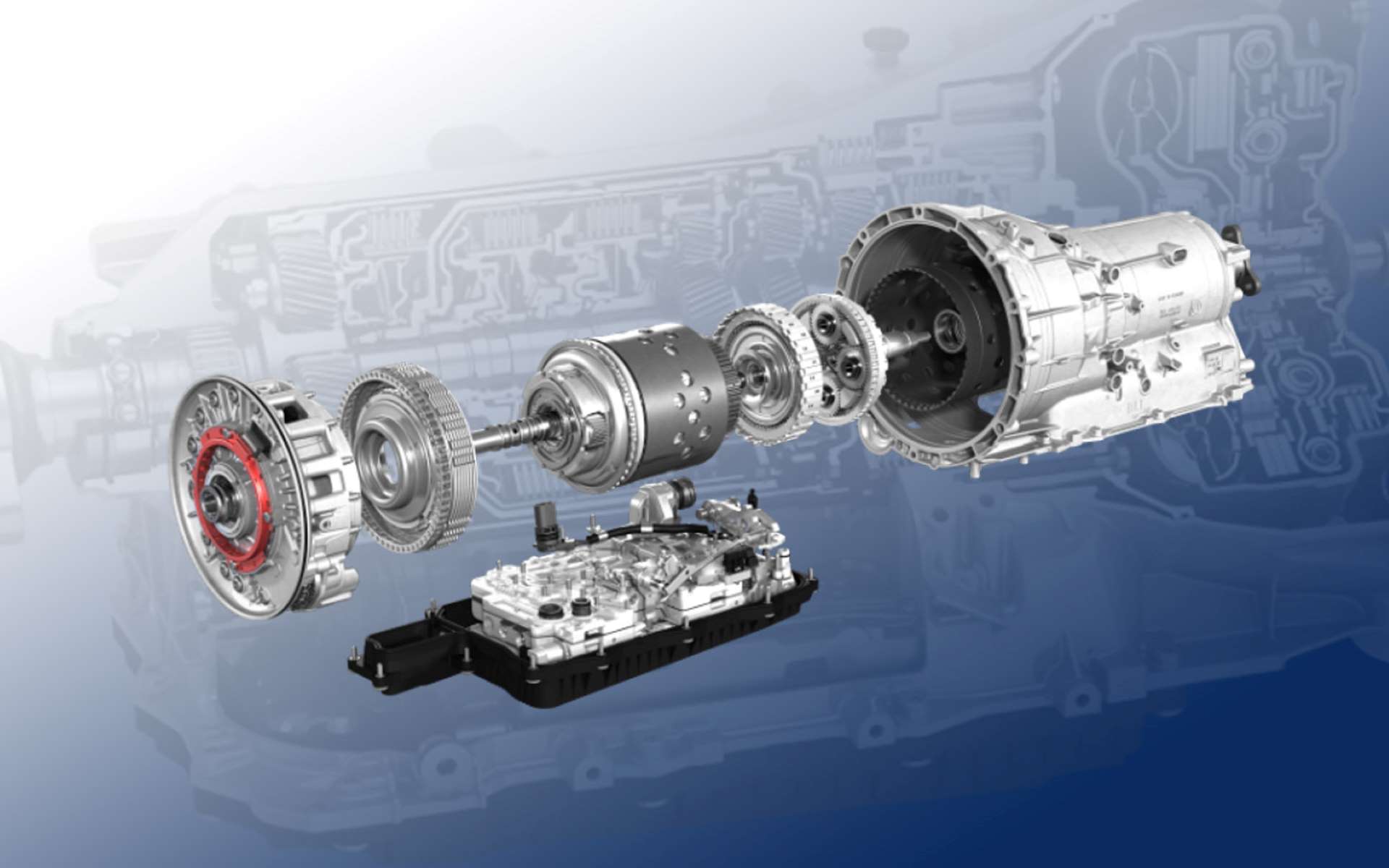

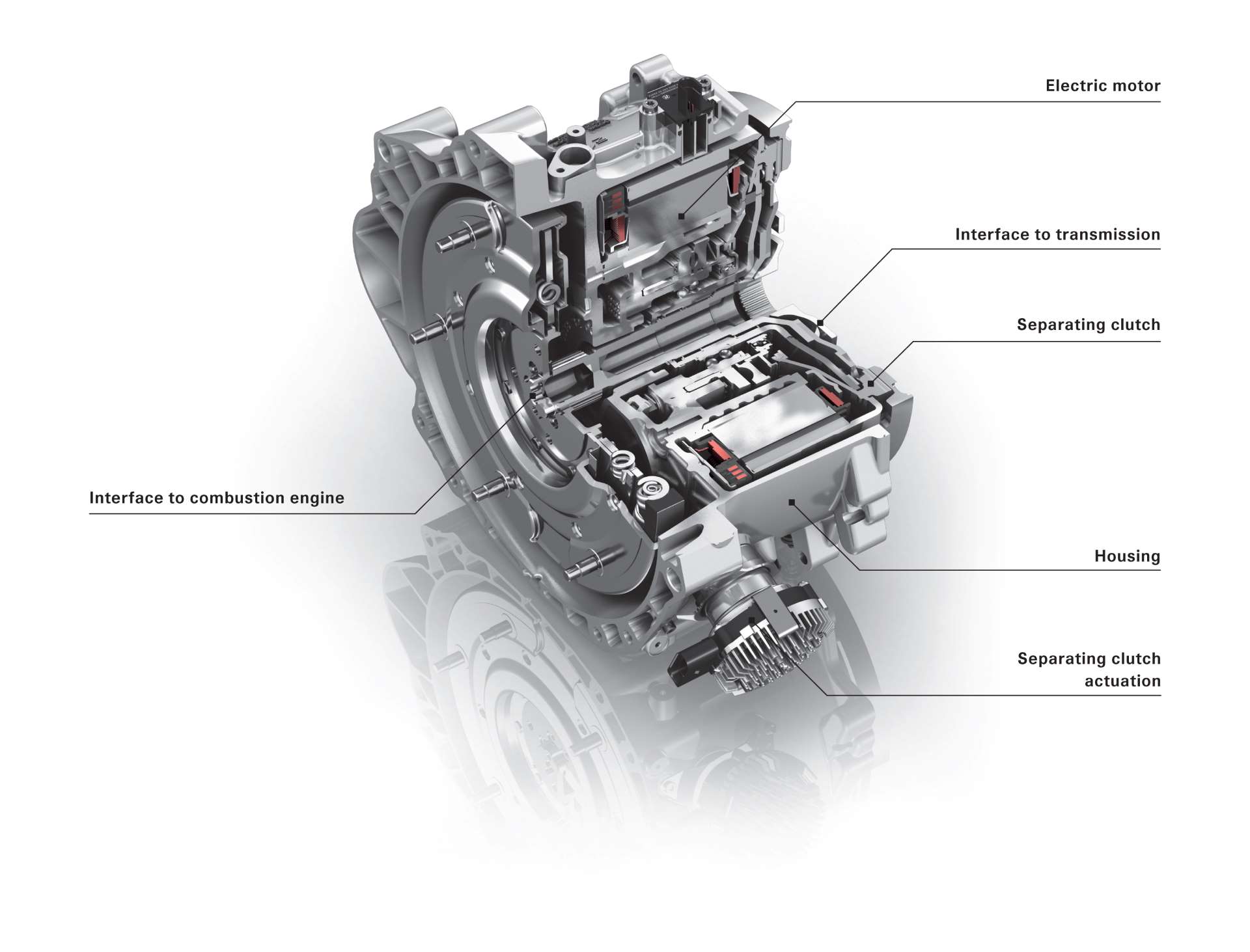

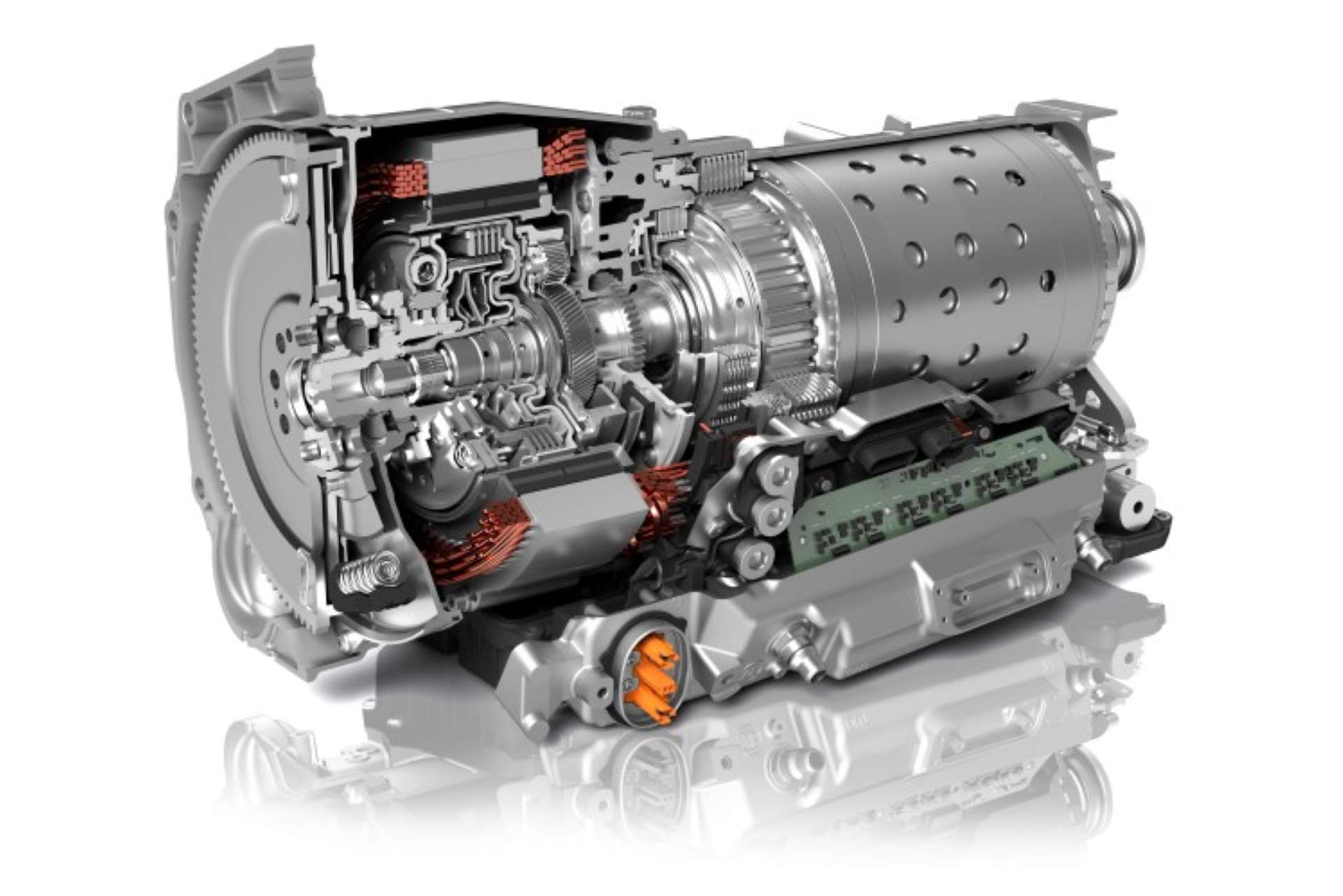

Hybrid Functionality

ZF prepared for an electric evolution, too, creating four different hybrid systems compatible with the 8HP. At the mildest is a 15kw electric motor installed in place of the torque converter. It can recharge itself under braking, provide an extra 200 NM of torque, assist with the stop/start function, and further reduce fuel consumption. At the wildest, a 100kw electric motor is fitted to the front of the gearbox. It is substantially larger and heavier than the 15kw unit but provides more upside. Rather than just assisting the engine, this motor can be used for fully electric operation or to drive the front axle on a normally rear-wheel-drive model while also providing double the torque figure of the 15kw unit.

All-Wheel Drive Compatibility

All-wheel-drive compatibility was another hurdle that ZF tackled for the 8HP. Again, crediting the modular design, there are three variations of all-wheel-drive systems that the 8HP can handle. First up is a standard transfer case bolted to the transmission’s tail like the units typically found in SUVs. Second, the transmission case can include the front axle drive and center differential, making it one complete unit. That style is in use in several Volkswagen Audi products. And last but not least is somewhat of a hybrid of the two previous systems for vehicles that utilize a “torque-on-demand” system, requiring front axle drive under specific circumstances only.

ZF 8-Speed Design Update

Five years was enough time for ZF to hit the drawing board and come back with a round of advancements for their 8HP 8-speed automatic, so in 2015, they unveiled the second generation of 8HP45, now called the 8HP50. The name change resulted from its increased torque capacity, up from 450 NM to 500 NM, though that was more of a byproduct of efficiency advancements.

Those advancements stemmed from ZF’s desire to improve on its engine downspeeding. Downspeeding lowers the engine’s cruising RPM while maintaining the requisite power to have the car continue at a set speed without slowing down. In the five years of development, engines grew stronger but more efficient. Because of that, ZF widened the ratio spread to 7.8, dropping the revolutions per minute by 50 across every gear, according to ZF. A lowered system oil pressure, an extra open clutch during deceleration, and additional springs in the shift elements were also new for the 8HP50, focusing on reducing drag.

ZF 8-Speed Transmission Problems & Leaks

As said above, the ZF 8-speed is an incredibly reliable transmission. In its nearly ten years of use, internal faults have been scarce, many of which have been user-related. If there is anything to look out for, it’s the occasional fluid leak. The two points of concern for leakage are the oil cooler connections and the Mechatronic sleeve.

ZF 8-Speed Oil Cooler Leak

The 8-speed uses an external transmission fluid cooler to help keep the transmission running smoothly during extraneous operation, such as heavy traffic or a high-performance situation. The inlet and outlet on the transmission for the cooler use standard o-rings to seal their connections. Through constant heat cycling, these o-rings can deform, allowing transmission fluid to leak on by. This type of leak can be identified by fluid running down from above the pan on the driver’s side.

ZF 8-Speed Mechatronic Sleeve Failure

The other thing you might have to contend with is a failing Mechatronic sleeve. Each vehicle using the ZF 8-speed is going to have an external computer sending and receiving signals from the transmission to relay that information to the other computers in the vehicle. The sleeve used to shield the electrical connections entering the transmission from its fluid can fail, allowing fluid to reach the connections. ATF on the electrical connections can cause error lights on the dashboard and a non-functioning transmission. Although the failed sealing sleeve was a much more prominent issue on ZF’s previous transmissions, it still needs to be noted.

ZF 8-Speed Neutral Safety Switch

Additionally, if the vehicle's battery dies, you won’t be able to shift the transmission, and it will be stuck in park. While having every function of the transmission be operated through electrical connections saves weight and space, it eliminates any mechanical way to shift the transmission. To get around that issue, ZF included a small bolt on the bottom of the transmission. It sits on the driver’s side, and when threaded in, releases the parking pawl inside the gearbox, shifting it into neutral. Use the video below to watch our DIrector of Motorsports, Nate Vincent, take you through the process of manually unlocking the 8HP.

ZF 8-Speed Service Intervals & Maintenance

Several automakers claim that the fluid inside their 8HP45-equipped models will last for the life of the transmission. That statement completely contradicts what ZF themselves say about their transmission. Automakers make those claims to help themselves meet pollution and emissions requirements. Lifetime fluid means less has to be produced and disposed of, thereby saving energy and the environment.

ZF calls for replacement trans fluid every 50-75K miles (80-120KM), or eight years, whichever comes first. It’s best to use ZF’s LifeGuard Fluid 8 when servicing your 8HP45. The fluid was designed by ZF for its transmission, essentially guaranteeing that it’ll perform as intended. Aftermarket companies, such as LIQUI MOLY, have their own fluid made to the ZF’s specifications that can be in place. When replacing the fluid, you should change the filter as well, and since the filter is part of the plastic pan, they are replaced as one piece.

BMW was the largest adopter of the first generation of the 8HP45, and it was used in just about every model they had before ZF updated to its second generation, the 8HP50.

FCP Euro offers a complete service kit for the ZF 8-speed automatic with all the parts you’ll need.

Automatic transmissions are very different from manuals. Inside them, there are thousands of pathways through which the transmission fluids flow. Its pressure, along with the electronics, operates the solenoids and valves responsible for vehicle operation. Because of these pathways, the filling procedure can be reasonably complex. It also means that all of the fluid never actually makes it out of the transmission. Filling them up isn’t the most precise process, so the amount of fluid necessary may vary between cars. To better understand how to service the 8HP45, watch the video below. In it, our BMW Catalog Manager, Gareth, completes a service on his 8-speed automatic. This video applies to all 8HP45/50s, regardless of the vehicle.

ZF 8-Speed Transmission Upgrades

The 8HP45/50 may only be rated to just under 400 lb-ft of torque, but ZF’s other 8-speeds, like the 8HP70, can hold significantly more. Swapping from an 8HP45 to 8HP70 is possible and has been done before in BMW’s 3-series. It requires a new flywheel, recoded TCU, the 8HP70, and some other supporting bits but gives you an OE-spec transmission capable of holding twice the advertised power of the 8HP45. Any more torque than that, though, and you might want to consider other options.

The easiest way to beef up your 8HP45/50 is with an upgrade package, like those offered by Pure Drivetrain Solutions. They offer four different packages; the weakest rated at 750 lb-ft and the strongest capable of over 1200 lb-ft of torque. Each transmission is fully disassembled and features stronger clutches, stronger seals, and a few modified internal pieces. The strongest gearboxes also receive shafts, hubs, and baskets made from billet aluminum. The N55 or B58 engines mated to the 8HP are capable of some serious power; these transmission upgrades will ensure their reliability and longevity.

ZF 8-Speed Transmission FAQ

Is the ZF 8-Speed Reliable?

We’re asked this question a lot, so we’d be remiss not to address it directly. ZF had plenty of data to use from their previous transmissions, the 5HP and 6HP, when designing the 8HP. Consequently, there is hardly anything to worry about when it comes to reliability and longevity. In stock applications, the ZF 8HP is reliable as it gets. Modified vehicles running stock transmission internals are reportedly very stout. The 8HP45 is no pushover when it comes to increased torque and horsepower demands. ZF seemingly undersold the torque limit in the name of reliability and longevity, allowing owners to take advantage of its strength. However, there is a finite torque limit for the 8HP45, and it gets rather expensive if you push right through it.

What cars use the 8HP45?

The ZF 8HP45 and its updates can be found in several BMWs, a couple of Chryslers, the V6 Ram 1500, a few Dodges, and several Jaguars. Here’s a complete list of vehicles that use the ZF 8HP45/50:

8HP45 / 8HP50

- BMW

- 2012-2019 F20 1-Series

- 2014-2016 F22 M235i

- 2012-2019 F30 3-Series

- 2010-2017 F10 5-Series

- 2011-2018 F13 6-Series

- 2009-2015 F01 7-Series

- 2011-2017 F25 X3

- 2014-2018 F26 X4

- 2011-2013 E70 X5 35i

- 2013-2018 F15 X5

- 2015-2019 F16 X6

- 2011-2014 Z4 Roadster

- Jaguar

- 2015-Present XE

- 2014-Present F-Type

- 2014-2019 Jaguar XJ

- Land Rover

- 2014-Present Land Rover Range Rover Sport

8HP45RE / 8HP50RE

The 8HP45RE was designed especially for Chrysler’s V6 powered models. Changes over the standard ZF 8-speed include extra friction plates in the clutch packs and a deeper fluid pan.

- Chrysler-Dodge-Ram

- 2015-Present Chrysler 300 V6

- 2012-Present Dodge Charger V6

- 2012-Present Dodge Challenger V6

- 2014-2017 Dodge Durango V6

- 2013-Present Ram 1500 V6

Is the ZF 8HP45 a dual-clutch?

The ZF 8HP45 is not a dual-clutch transmission, but rather a traditional torque-converter automatic. However, the lightweight internal components reduced internal drag, and the advanced valve body allows the 8HP to shift nearly as fast as a DCT but without the complex and expensive design. The 8HP is cheaper to produce, cheaper to maintain, easier to modify for greater power, and is just as fuel-efficient.

If you have any questions about the ZF 8-Speed transmission, or if you would like to see something added to this guide, leave your thoughts in the comments section below.