- 09/28/2023

- 3 Min Read

- By: Gareth Foley

How To Time-Sert An Aluminum BMW M54 Engine Block (BMW M52TU, M54, M56)

The BMW M52TU, M54, and M56 engines are all related by their aluminum engine blocks. Until then, all prior M-series straight-six engines had used iron cases, making them strong but very heavy. The switch to an aluminum block with iron liners shed weight over the front axle, subsequently improving performance and cooling abilities. However, the aluminum’s relative softness has also become a weakness. Despite their solid reputation, anyone messing with an M52TU, M54, or M56 cylinder head must worry about pulling cylinder head bolt threads.

We call this the “forbidden slinky,” and there is nothing worse than seeing the threads coiled around the head bolt during removal or worse when you install a new head bolt and righty tighty becomes righty loosely.

This phenomenon can happen in a variety of ways, with the most common head bolt thread failure being due to overheating. In that situation, the head warps and pulls upward on the block via the head bolts, and something has to give. The other common source of the forbidden slinky is during an engine rebuild in which the installation of the new head bolt pulls the threads out. When that happens, the threads are already weak and doomed to fail. The fact is that the steel head bolts are being threaded into an aluminum engine block. The threads in the engine block are part of the casting and are machined. They’ll never be as strong as steel threads.

If this happened to you or you are preparing a rebuild, we strongly recommend Time-Serting the engine block. Using Baum tools engine block drill jig, you can permanently fix and repair the engine block threads for the head bolts—even with the engine still in the car. It's also possible without the drill jig, but the fact is the jig prevents you from drilling or tapping crooked and from going too deep into the engine block. Baum designed this jig to work with a generic M10x1.5mm Time Sert kit (TS1015), so you must order additional Time Serts (TS10155) for this specific repair, which measures M10x1.5x24.5mm.

Why Time-Serts?

Time-Serts are the preferred solution for this type of repair because of how it locks into the material it’s being installed into. Time-Sert explains it best:

“TIME-SERT® inserts are self-locking, having an actual locking feature that will prevent them from coming out when a bolt is removed. On installation, the bottom few internal threads of the insert are cold rolled to expand into the mating external threads of the base material, locking the insert in place.”

Once in place, the steel inserts lock into the aluminum and take the brunt of the forces coming from the head bolt. Even under significant pressure from big horsepower, the inserts shouldn’t pull out of the aluminum.

How to Time-Sert Your BMW M52TU, M54, or M56 Engine

With the cylinder head removed from the engine, you’ll first want to clean the mating surface and ensure the cylinder deck is straight. The maximum deviation on the M54 is 0.15mm. If the engine block is straight, continue on. Clean the mating surface and tape off the entire top of the engine block using painter's tape. This will prevent material from falling into the oiling jacket or cooling jacket as you carry out the procedure. You will also want to remove the cylinder head dowels.

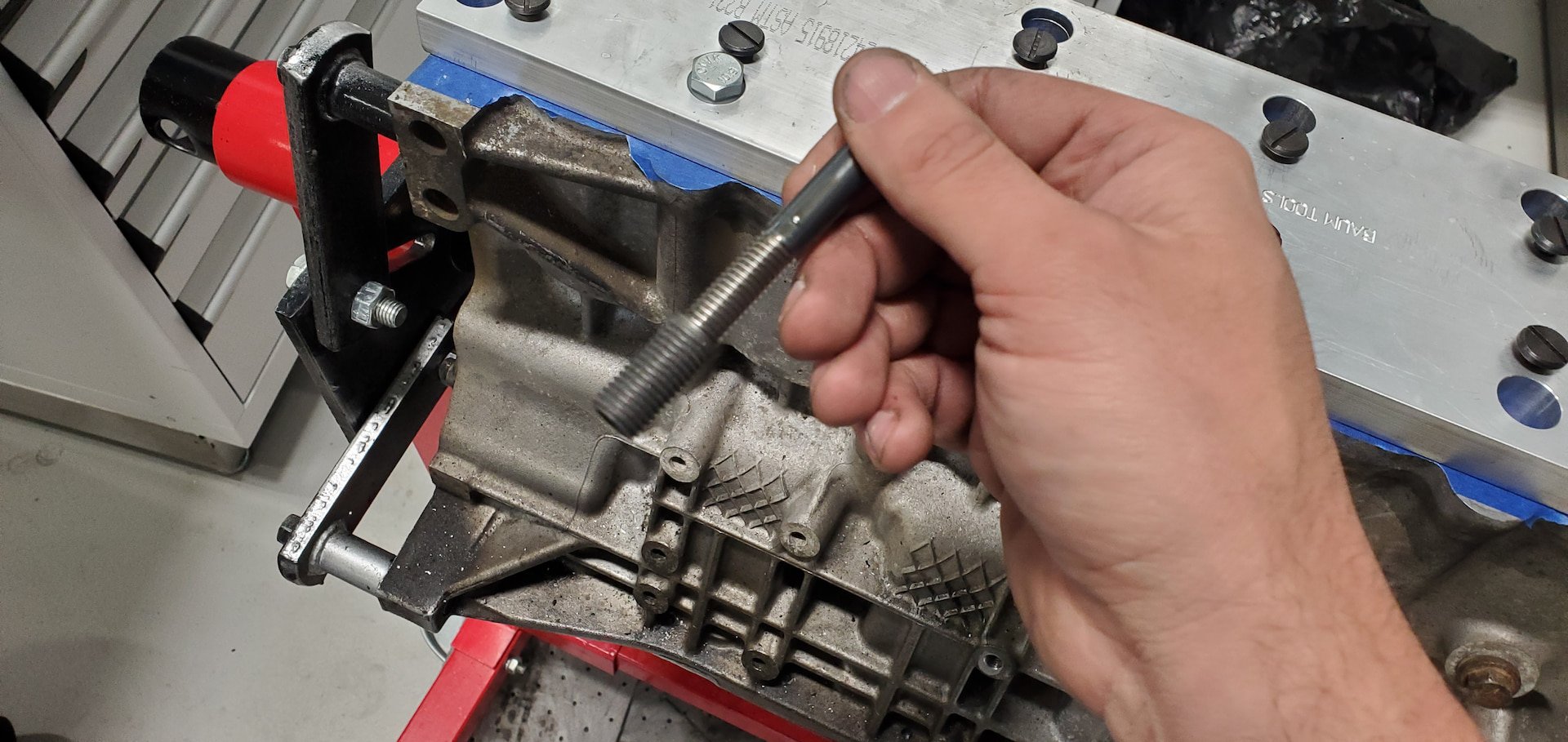

The Baum tools drill jig uses two coolant passages on the back of the engine block to square the jig to the cylinder head. You might find the fit of the dowels to be tight, and if that’s the case, you can use a small file to remove any surface corrosion from these passages. Without the corrosion, the jig should fall into place. Included with the jig are two delrin bushings and two drill guides. The Teflon bushing is used in conjunction with M10x1.5x40mm bolts to lock the jig into place on top of the engine block.

I used these bolts on both sides of the block close to the holes I was repairing.

Steps for Time-Serting Your BMW M52TU, M54, or M56

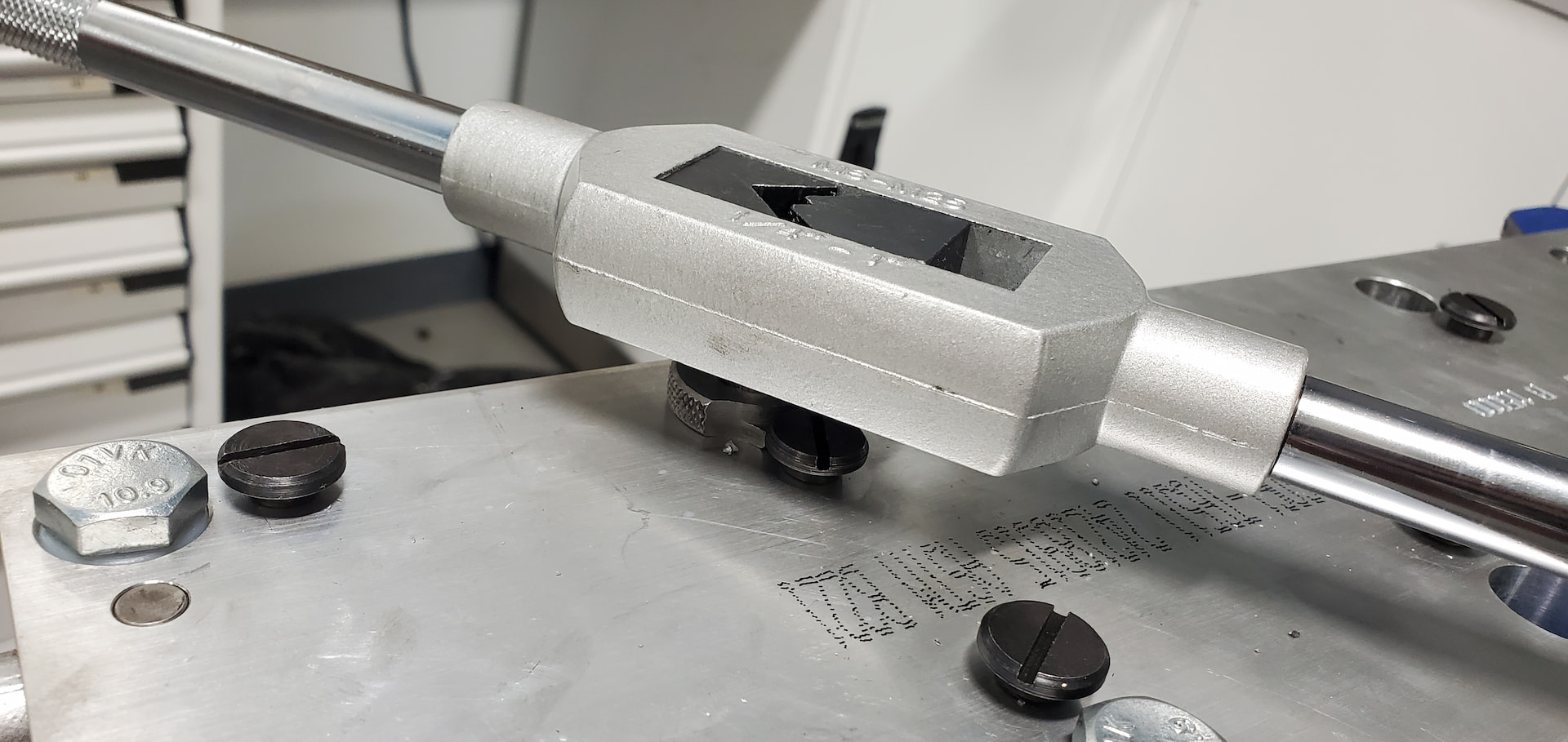

Step 1: Remove The Old Threads

Place the drill guide into the jig and use a tap and driver handle with an M10 bit to cut the factory M10x1.5mm threads out of the block. You do not need to use a drill as the material is soft, and it’s simply removing the threads. This should be very easy to do. Halfway down, use a vacuum and compressed air to clear out the aluminum chips. After cleaning the bit and the hole, finish removing the material from the hole to the stop. Repeat this step for every hole you're repairing.

Step 2: Countersink The Engine Block

Remove the drill jig from the engine block and switch to the countersink tool. The time sert needs to sit below the surface of the block where the head sits. This countersinking tool stops cutting at a specific depth and is self-piloting. Again, you do not need a drill for this operation and can use a tap driver/handle to remove the needed material. The tool will stop removing material when it reaches its maximum depth. Make sure all chips are cleaned from the surface and from the hole.

Step 3: Tap The Engine Block

Reinstall the drill jig along with the M10 guide for the M10x1.5mm tap. You will now be tapping the hole for the Time-Sert. The jig/guide will make sure the tap starts straight. Because the aluminum is soft, it will cut very easily with little force. Every few turns or so, back the tap off to clear any chips. WD40 is the preferred lubrication for cutting into the aluminum. After tapping the hole, ensure it’s clear of any debris/chips.

Step 4: Install The Time-Sert Insert

Clean the hole using some brake parts cleaner and, using compressed air, thoroughly dry the hole from any moisture. Then, use the Time-Sert installation tool to prepare the insert for installation. This installation tool will expand the insert into position and set its depth. Lightly oil the installation tool before installing the steel threads with a tap driver/handle. I used some red Loctite with this installation for extra insurance, but it’s unnecessary.

As the insert goes into the hole, it will bottom out, and then the installation tool will start to thread into the tool. Keep going until you feel tightness. At this point, go a little further until it becomes loose, but stop before bottoming out the tool in the insert. The tightness/tension is the installation tool spreading the Time-Sert into position which locks it into the material.

Congratulations. You have repaired the threads in your M52TU/M54/M56 engine block with new threads that are significantly stronger and won’t fail. Now, you can reinstall your cylinder head without worrying about pulling threads. For more helpful guides and DIYs, continue to follow along here on our DIY Blog, and be sure to subscribe to our YouTube channel.